Maximize Uptime with Predictive Maintenance for Manufacturing

Trusted by 800+ Clients, Driven by Excellence for Two Decades

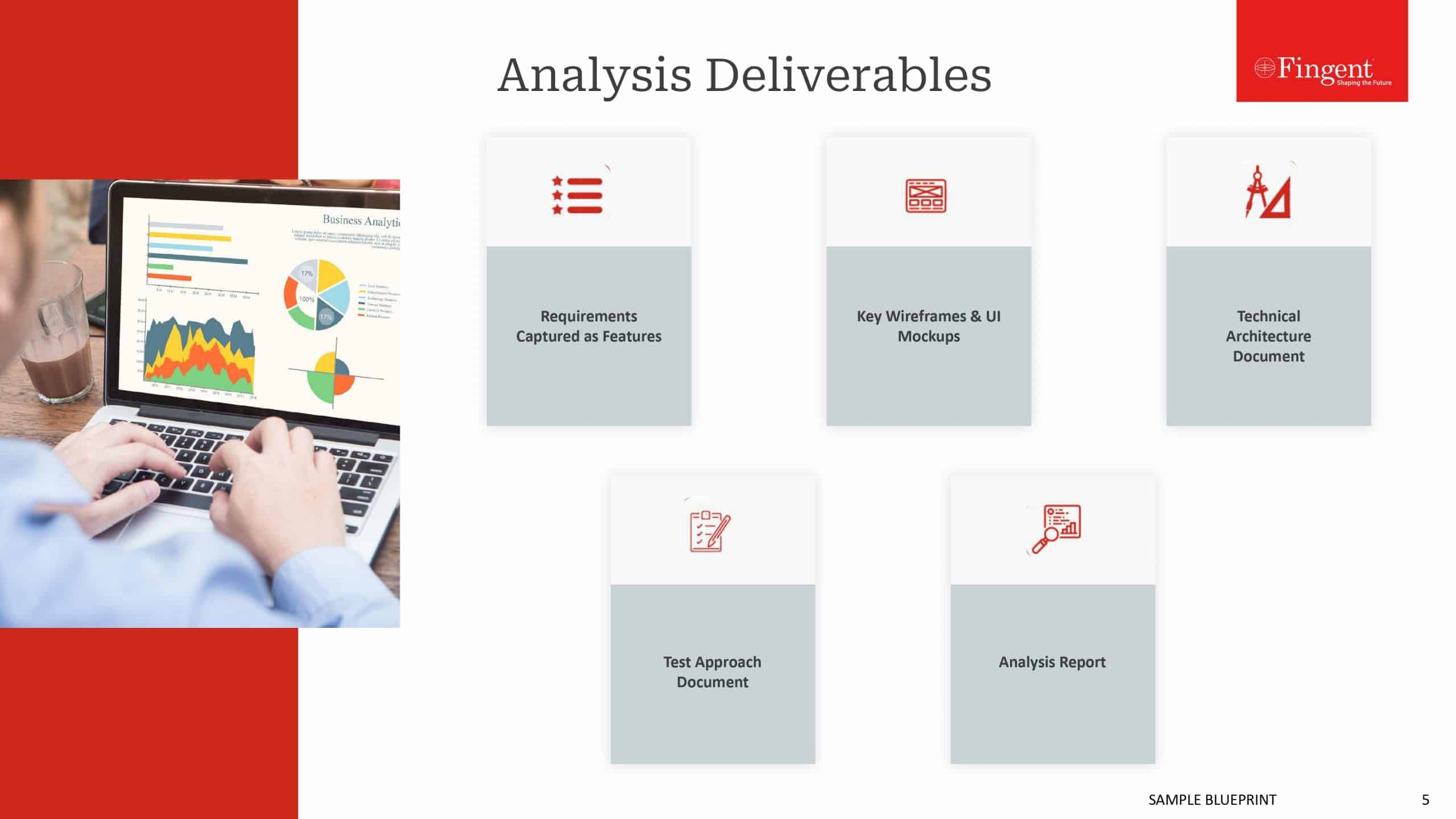

Must-Have Features for Effective Predictive Maintenance in Manufacturing

Stay ahead of equipment failures. Let’s build a solution that works exactly the way you need it!

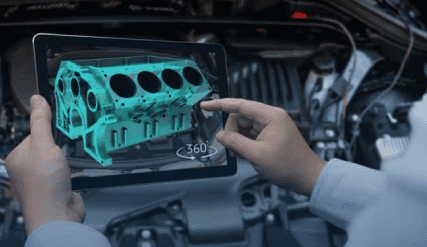

01 Real-Time Equipment Monitoring

02 AI-Driven Failure Prediction

03 Custom Alerts & Notifications

04 Maintenance Scheduling Optimization

05 Historical Data Analysis

06 Integration with Existing Systems

A Glimpse of Our Success Stories

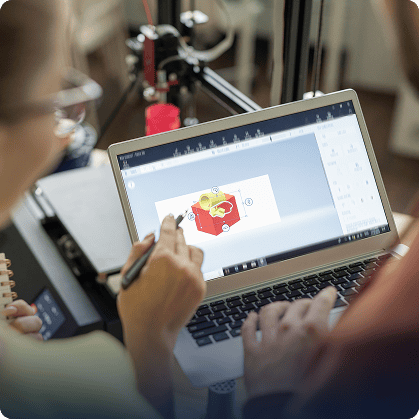

Tailored 3D Web Configurator for Cabin Designs

A cabin and storage shed manufacturer based in Ohio elected to work with Fingent in the creation of a bespoke 3D Web Configurator. This innovative solution enriches customer interactions by offering novel self-service possibilities and an immersive user experience.

Solution Highlights:

- Interactive floor plans and designs

- Real-time 3D visuaization

- Accurate pricing estimation

- Seamless integration with the existing system

Standardizing International Operations with SAP S/4HANA

AGP Group, a global leader in high-tech glazing manufacturing with multiple production facilities and technology innovation centers, aimed to standardize quality by streamlining operations across all its plants. While most locations operated under a unified global SAP ERP system, one facility was still functioning on disparate systems. Fingent successfully aligned its operations with the global standard through a seamless migration to SAP S/4HANA.

Solution Highlights:

- Unified business processes

- Streamlined reporting

- Consistent performance tracking

- Reduced maintenance costs

Minimize Downtime. Maximize Efficiency. Transform Your Factory Operations.

Hear from Our Clients

"Fingent was quick and helpful in mitigating arising issues."

Direct of Development, Healthcare Publishing Company

5.0

Quality

5.0

Schedule

5.0

Cost

5.0

Willing to Refer

5.0

Project Summary

Fingent partnered with a healthcare publishing company to deliver custom software development services aimed at modernizing their digital presence. The project involved migrating 33 legacy websites to the React framework, providing a robust and future-ready solution.

"The entire process has been really smooth — working with Fingent has been a lovely experience."

VP of Sales & Marketing, Kogland Commerce Pvt Ltd

5.0

Quality

5.0

Schedule

5.0

Cost

5.0

Willing to Refer

5.0

Project Summary

Fingent partnered with a premier B2B e-commerce marketplace to upgrade their website to Magento 2. The team also integrated the client’s Odoo CRM. Fingent provides continuous support and maintenance for their website.

"I like the quality of their deliverables, the timeliness with which they deliver, and the budget."

Co-Founder & CTO, Chemical Safety Software

5.0

Quality

5.0

Schedule

5.0

Cost

5.0

Willing to Refer

5.0

Project Summary

Fingent developed a software solution for a chemical safety company, leveraging Microsoft technology for UI, development, and QA. The team also provided business analysis to ensure a comprehensive and effective solution.

Our Other Manufacturing Solutions

Fingent - Your Trusted Partner For Manufacturing Software Development

Helping Businesses Since 2003

Latest Technology & Agile Approach

Skilled Techno-Functional Resources

Round-the-clock Support

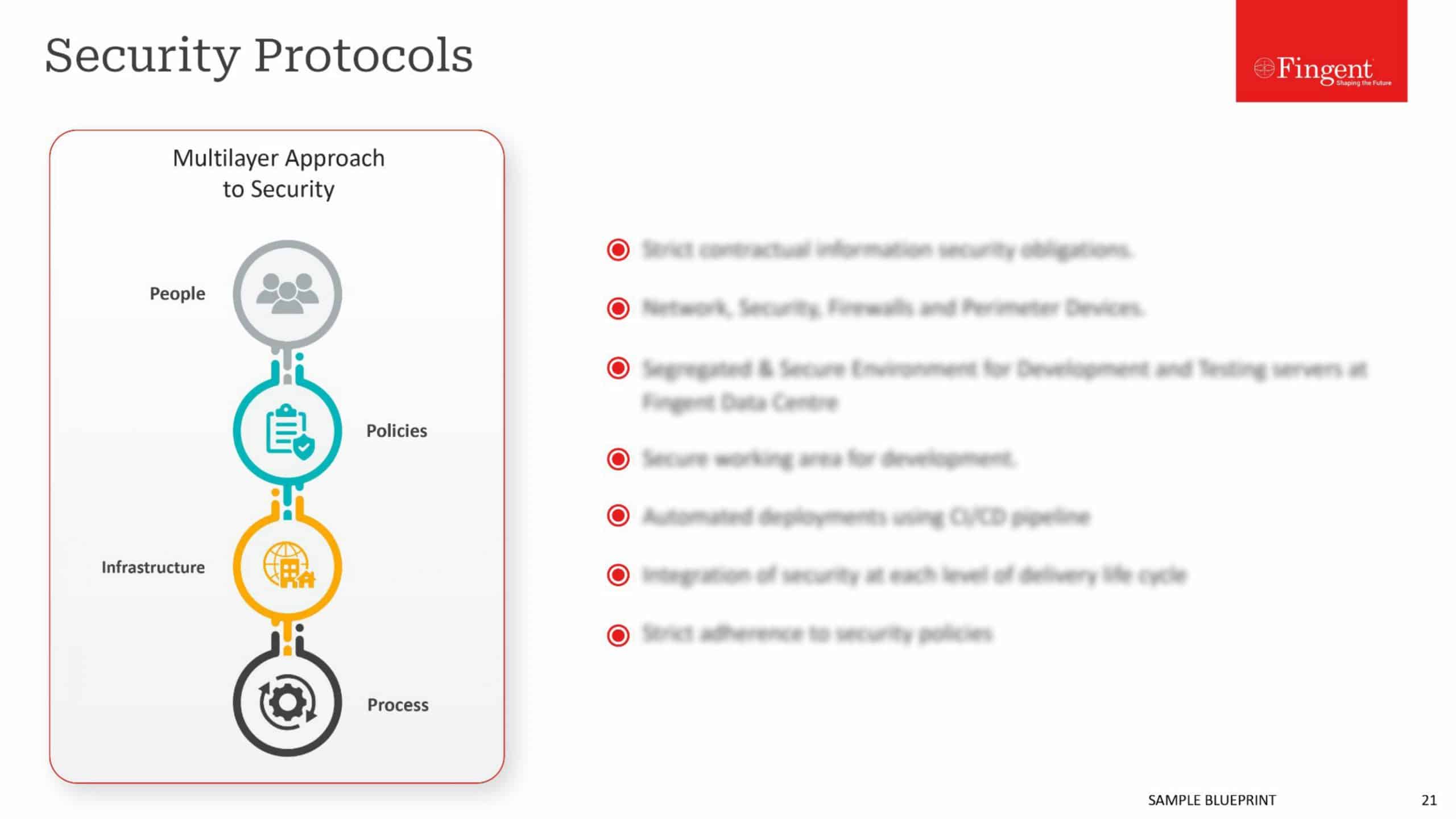

Robust Security Measures

Quality Assurance

Here’s How We Can Help You!

Connect & Collaborate

We deep dive into your business goals, processes, and challenges to ensure our solutions align with your vision.

Innovate & Develop

Using cutting-edge technologies, our team crafts a tailored ERP/MRP solution designed to meet the specific needs of your manufacturing operations.

Support & Enhance

Our partnership doesn’t end at delivery - we provide ongoing support, performance monitoring, and continuous enhancements to keep your system efficient and future-ready.

Frequently Asked Questions

What is predictive maintenance, and how does it work?

What kind of ROI can I expect from implementing predictive maintenance?

What types of equipment can be monitored with predictive maintenance?

Is predictive maintenance difficult to implement in an existing facility?

Will this integrate with my current ERP, MES, or CMMS system?

How secure is the data being collected and transmitted?

More Insights on Manufacturing Software Development