Category: Logistics and Supply Chain

Can Cloud based Logistics Platforms help you? The logistics game is changing fast! The industry is under immense pressure to improve its efficiency and reduce costs. That is its one shot at enhancing customer satisfaction. For years, traditional logistics management systems have struggled. Outdated technology slowed their processes. But now, technology brings a game changer for businesses: Cloud based Logistics Platforms!

With these smart systems, your company can get real-time insights and boost scalability. It will help optimize your supply chain to get maximum efficiency. Are you prepared to safeguard your operations for the future? Let’s get started.

What Is the Primary Purpose of Using Cloud Based Collaboration Tools in Supply Chains?

Cloud-based collaboration tools aim to enhance teamwork in supply chains. They let people share information quickly and easily, no matter where they are. This helps teams work together better, make decisions faster, and stay organized. These tools improve efficiency and lower costs.

Supply chains thrive on precision. But when communication slows and data scatters, mistakes happen. Research from Gartner reveals that bad data costs companies an estimated 15% of their revenue, with the average financial impact reaching $9.7 million per year. Here is where cloud-based solutions come into play.

They eliminate silos and bring everyone involved onto the same page. Cloud-based services offer immediate access to data. Logistics companies can prevent interruptions, reduce errors, and make quick, smart choices. They improve supplier collaboration, resulting in reduced bottlenecks and greater overall efficiency.

Struggling With Outdated, Disparate & Disconnected Logistics Systems? It’s Time To Up Your Game with Cloud-based Logistics Platforms!

Top Benefits of Cloud-Based Solutions for Logistics Management

Statistics indicate that many are switching to the cloud. The global cloud logistics market is expected to reach US$ 46,313.9 million by 2030, growing at a rate of 13.6% per year from 2025. This growth shows businesses are recognizing the benefits of Cloud-Based Solutions for Logistics Management. Here are some of those benefits:

-

Real-time tracking and Visibility

The Challenge

Logistics teams often lack information regarding the whereabouts of shipments. This results in setbacks, misplaced packages, and dissatisfied customers.

The Solution

Cloud-based services offer comprehensive shipment tracking featuring real-time GPS information. This gives logistics managers clear insights. It helps them optimize package routes and cut down delays in delivery. It also addresses any kinds of disruptions that we expect on delivery routes. Customers benefit from accurate ETAs and automated notifications. These features help build trust in the brand and boost satisfaction with services.

-

Scalability on Demand

The Challenge

Customer requirements change throughout the year. When demand spikes, logistics systems find it hard to cope with the sudden pressure. They have to scale operations but doing so without incurring large upfront costs becomes difficult to achieve.

The Solution

Cloud-based solutions help businesses to scale their operations easily. You do not need expensive hardware upgrades to achieve that. Cloud platforms can tackle it all. They handle adding fleet vehicles, expanding warehouses, and managing seasonal surges. This lets businesses grow as they need, without the stress of a fixed infrastructure.

-

Cost Savings

The Challenge

Inefficient logistics often lead to high operational costs. This happens due to manual errors, poor route planning, and fuel waste.

The Solution

Say goodbye to unnecessary expenses with cloud-based solutions. These systems provide AI-driven route optimization. Workflows are automated and the system works on predictive analytics. These processes help cut fuel use, reduce human errors, and improve warehouse storage.

Businesses can shift from costly, physical IT setups to affordable cloud services. This change helps free up capital. This lets companies invest in other growth initiatives that will help them over time.

-

Better Teamwork

The Challenge

When warehouses, drivers, suppliers, and customers don’t communicate well, it can cause problems in logistics. This often causes delays in the process.

The Solution

Cloud based logistics platforms integrate communication tools like instant messaging, automated alerts, and shared dashboards. This ensures that all stakeholders remain informed at all times. Enhanced communication results in more effective teamwork, faster reactions, and reduced misunderstandings. This results in a supply chain that is more coordinated and effective.

-

Security and Compliance

The Challenge

Companies deal with sensitive client information on a daily basis. Data breaches, fines, and not following industry rules don’t look good for security. This can put businesses at serious risk.

The Solution

Cloud-based platforms prioritize keeping data safe. They offer strong security features, like encrypted storage and multi-factor authentication. These protect against intruders. Their AI-driven threat detections safeguard sensitive data. Many of these platforms have built-in compliance tools. These tools help logistics companies follow important guidelines. This helps prevent costly violations.

Real-world Success Stories with Cloud Based Logistics

1. Turn Chaos into Control

The Challenge

Shipping companies lose a lot of time and money due to outdated logistics systems. Inefficient tracking systems and fleet management cause frequent delivery delays.

How Cloud-Based Tech Helps

By using a cloud based logistics platform, shipping companies can see their whole fleet in real time. This allows AI-powered route planning and an automated maintenance schedule.

The result? Delivery delays decrease significantly. Fuel use improves and becomes more efficient. Vehicles experience less wear and tear, which leads to substantial cost savings.

2. Warehouse Woes Fixed in E-commerce Giant

The Challenge

E-commerce players face frequent inventory mishaps. There are errors in fulfilment. Increasing order volumes become difficult to keep up with.

How Cloud-Based Tech Helps

A cloud-powered warehouse management system transforms operations by automating inventory tracking. The team can improve demand forecasting and streamline order fulfilment processes as a result. With real-time inventory insights, stock discrepancies drop. A large margin reduces customer delivery times. This helps grow clientele, strengthens brand loyalty and boosts repeat sales.

3. Cold Chain Logistics Enhanced

The Challenge

Global food distribution companies struggle with inconsistencies in temperature during transport. Due to this, many perishable goods are spoiled in transit. These goods cost a significant amount of money, and there are huge financial repercussions. Apart from that, many regulatory issues crop up.

How Cloud-Based Tech Helps

Integrating IoT-enabled cloud tracking helps monitor temperature and humidity in real-time. Automated alerts are sent to drivers and logistics managers. This helps them take quick action. This helps companies comply with food safety regulations and reduce waste.

4. Meeting Customer Demands Efficiently in the Retail Supply Chain

The Challenge

A national retail chain faced issues with delayed shipments and stock imbalances. This resulted in frequent out-of-stock scenarios and lost sales.

How Cloud-Based Tech Helps

A cloud-based supply chain management system enables real-time inventory tracking and automated restocking. An AI-driven forecasting system cuts down stockouts and boosts supply chain efficiency. Stores can keep shelves full, which keeps customers satisfied.

Discover Your Possibilities with Custom Logistics Software Development

How Fingent Helps Logistics Companies Stay Ahead

In today’s fast-paced world, there is no time for errors. Cloud based logistics platforms are a must if you want to stay relevant. Be it real-time tracking or automation and cost savings, the cloud has got your back. It is the key to staying competitive.

Fingent empowers logistics companies to transform their supply chain. We leverage cloud technology, AI analytics, and automation for better results.

We have worked with clients globally helping them reduce internal workloads by 50%, increase their customer base by 43% within 6 months, gain a 60% increase in employee satisfaction and more.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Managing a warehouse need not be so hard! A Cloud based warehouse management system helps warehouses get their act together and focus on what’s most important. Overly packed workers, stockouts, overstocking, delayed order processing, disgruntled customers. All such inefficiencies can be eliminated with cloud-based WMS.

What’s in a cloud based warehouse management system that tick all the boxes for efficient warehouse management? Is it worth looking into for your business? This blog will give you all the answers you need.

Build Smart WMS Solutions That Boost Your Business Performance

What are Cloud-Based Warehouse Management Systems?

Imagine managing a warehouse on sticky notes and over the phone—chaos, right? That’s where cloud-based warehouse management systems or cloud based WMS come in.

An organization’s web-based central to track everything from inventory to order completion on the internet is called a cloud-based WMS. As in the name, the major advantage of these systems is that they are based in the cloud. This brings in many benefits in itself. It includes reliable backup and security during disasters, greater mobility for management on the go, and more. However, cloud based WMS is so much more than that. It has the astounding ability to efficiently streamline complex warehousing tasks while maintaining real-time visibility across data.

What are the Advantages of Cloud-Based Warehouse Management Systems?

Adopting a cloud based WMS is like trading in a bicycle for a sports car. When switching to a cloud-based WMS, everything moves faster, smoother, and with a lot less effort. Here are some unique benefits from cloud-based WMS:

1. Automatic Software Updates & Security Improvements

You no longer have to upgrade the software format or install fresh security patches with a cloud-based WMS. All updates are done incidentally by the service providers themselves. Your system will automatically get the latest features and security protocols without you having to lift your finger.

2. Disaster Recovery and Backup

Spill coffee all over your warehouse computer, and you’ll face a complete system shutdown. Traditional on-premise systems could result in losing important data due to accidents. However, with cloud-based WMS, the data will be securely shifted to the cloud from backups. It reduces the chance of data loss and allows quick recovery from any sudden failure. This means peace of mind to businesses during disasters or system failures.

3. Lower Environmental Impact

Running your servers requires a lot of energy, adding up to a much larger carbon footprint. The top cloud based WMS solutions are hosted on shared but optimized data centers with energy efficiency in mind. This greener route helps reduce your company’s environmental impact. It’s great for your sustainability report, too!

4. Seamless Collaboration Across Teams and Locations

A cloud based WMS is just like a shared document in a cloud-based system where multiple people can edit it simultaneously. Everyone in your supply chain, suppliers and customers, can observe the same up-to-date information. This is irrespective of where they are. You thus have better communication, quicker decision-making, and fewer errors due to obsolete information.

5. Predictive Analytics to Proactively Make Better Decisions

Advanced analytics and AI-driven tools form a part of most cloud based WMS solutions. These tools analyze historical data and predict your future demand. This way they help you get ready for stock fluctuations. It ensures you have no surprise out-of-stock issues or over-ordering. You get a perfectly balanced and well-forecasted inventory.

6. Increased Customizability and Integrations

A cloud based Warehouse Management System is not one-size-fits-all. With a good technology partner, your WMS can be fitted with custom-tailored features to fit your business. This includes your ERP, CRM, or even out-of-the-box integration with certain e-commerce platforms. It’s like a tailored suit for your warehouse that fits perfectly and adapts to the changes in your business as it grows.

7. Mobility for Management on the Go

For many warehouse managers, being on the move and not caged behind a desk is necessary. This is where cloud-based warehouse management systems help. These systems can be accessed from any mobile device, allowing managers to see, approve, and adjust operations from anywhere. It’s like having your whole warehouse in your pocket, whether you’re out there on the floor or on a well-deserved vacation.

8. Continuous Improvement with Feedback from the Community

Good tech providers commonly go into feedback loops with users in cloud based WMS to ensure that product evolution is driven by customer needs. As users point out pain points or make suggestions for improvement, over time the system gets smarter and better. It is like a shared community of warehouses that help build the system incrementally to be more efficient with every update.

Automate Warehouse Operations For Streamlined Operations & Reduced Labor Cost

Traditional vs. Cloud-based WMS: What’s the Real Difference?

Comparing a cloud based warehouse management system to traditional, on-premise WMS platforms is like comparing streaming music on Spotify to owning a CD collection. Sure, the CDs might feel more in control, but Spotify can give unlimited access to everything, anytime and anywhere, without the clutter. That’s what cloud WMS brings to the table.

Here’s a breakdown of how cloud based WMS platforms differ from traditional WMS:

1. Anywhere, Anytime Accessibility

Traditional WMS systems are usually locked into one physical location. This really means you need to be on-premises, at best, or fiddle with complex VPNs to stay in touch with what’s happening inside the facility. With a cloud-based WMS, you only require an Internet connection. You could be sipping coffee at the warehouse, meeting on the other side of the world, or even just at home. You can still overview inventory, operate orders, and make real-time decisions from any device.

2. Scalability Without Headaches

With a regular WMS, growing your business often means investing in more servers and IT infrastructure. That can very quickly become a huge logistical and financial headache. By contrast, cloud-based WMS platforms scale easily: you pay only for what you need. Growing from one warehouse to five? Easy! Your cloud solution grows with you and doesn’t require any costly upgrades or new hardware.

3. Reduced Upfront Costs

With traditional WMS, you had to invest in expensive hardware, IT staff, and subsequent maintenance. On the other hand, when you go onto a cloud-based WMS, you pay your subscription fee, and the provider takes care of everything, from security to updates. This model reduces upfront costs while freeing you up to run your warehouse, not servers.

4. Faster Implementation and Updates

A traditional WMS requires months for setup, whereas a cloud-based WMS goes live in days or even hours. Because the updates are automatic and handled in the background, there’s no need for an IT cavalry if the system needs a tune-up.

5. Security and Compliance by Default

Cloud-based WMS is more secure than traditional in-house systems. Tech providers invest in top-tier encryption, disaster recovery, and compliance with international regulations. This means your data is protected 24/7.

6. Smoother Integration with Modern Tools

Traditional WMS platforms rarely work well with newer technologies such as IoT, robotics, and AI-powered systems. Cloud-based WMS platforms are built for modern enterprises and work well with innovations at the edge. It is the difference between using a rotary phone and a smartphone—one struggles to keep up, and the other is ready for whatever the future brings.

Read more: Warehouse Management Systems: Business Applications & Case Studies

Are Cloud-Based Warehouse Management Systems the Future?

Migration to cloud-based WMS is not a fad but the future of warehouse operations. Why? Let’s look at some very unique reasons that go further than just speed and cost savings.

1. Real-time data accuracy

This is one major contributing factor to cloud-based WMS being the future. Precise records of everything—from ‘Inventory’ to ‘Order Fulfillment’—are maintained for modern warehouses. Most traditional systems have a gap in the time between capture and processing. Cloud-based platforms present real-time visibility of literally every aspect of your operation—much like knowing your bank balance on the go. This level of real-time accuracy is not just a plus; it is fast becoming a prerequisite given growing customer expectations.

2. Innovation readiness

The cloud-based WMS systems are built on a foundation to integrate seamlessly with new technologies coming up, such as AI, machine learning, and IoT. Just visualize a future wherein your warehouse could reorder its stock automatically, optimize layouts, and even manage robotic workers—all on account of intelligent cloud integration. Now, traditional systems could hardly cope with such a pace and innovation.

3. Global synchronization

This is another reason cloud-based WMS platforms are here to stay. As e-commerce goes on booming, business scales globally, and warehouses in every different country or continent should be on the same page. A cloud-based WMS means that warehouses worldwide have the same data. This means consistency and not the chaotic nightmare of dealing with a plethora of systems.

4. Sustainability

Lastly, sustainability is the future of warehousing, and cloud-based solutions are inherently much greener. Reducing physical servers helps lower the energy consumption of a company and its overall carbon footprint, hence making your warehouse more sustainable in the long run.

Power Your Warehouse Operations With The Right Technologies

How Fingent Can Help Leverage This Technology

At Fingent, we have experience adopting a cutting-edge cloud-based warehouse management system specifically tailored to businesses’ requirements. We ensure that the move from traditional WMS platforms toward newer, cloud-based solutions is seamless. By incorporating our experience, we aim to help unlock a company’s full potential from its warehousing operations.

Our end-to-end WMS services include strategy, implementation, and continuous support. It’s not just about the technology but a partnership that ensures your warehouse is always at peak efficiency. From advanced AI integration to simplifying the user experience, Fingent ensures your cloud-based WMS stays updated on the latest trends and innovations.

Explore your possibilities with a smart custom-built WMS solution today! Contact us now!

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Warehouse operations that run like clockwork. Perfectly stocked, tracked, and delivered inventory, and customers who can’t stop raving about your efficiency and delivery times—that is the ultimate goal! Can IoT in warehouse management help attain this level of efficiency? Let’s find out!

Providing efficient, smart, and sustainable warehouse solutions is possible. All you need is the right technologies. IoT is steadily revolutionizing warehouse management by connecting devices, machinery, and inventory. It’s helping leading businesses globally drive efficiency, reduce costs, and transform operations in real time.

Here’s more on how IoT solutions for warehouse management tackle common challenges and improve business performance.

Build Smart WMS Solutions That Caters To Your Specific Warehouse Management Challenges

What is the IoT in Warehouse Management?

The Internet of Things is a network of electronic gadgets embedded with technology. IoT enables them to connect and exchange data over the internet. These devices can collect and share data, communicate with each other, and be controlled remotely.

The Internet of Things (IoT) is a viable solution to enhancing efficiency in various industries. IoT in Warehouse Management can help perform a wide range of tasks. It can perfect tasks from monitoring inventory levels to optimizing workflow and providing real-time insights. It can revolutionize processes using basic automation to high-grade predictive analysis.

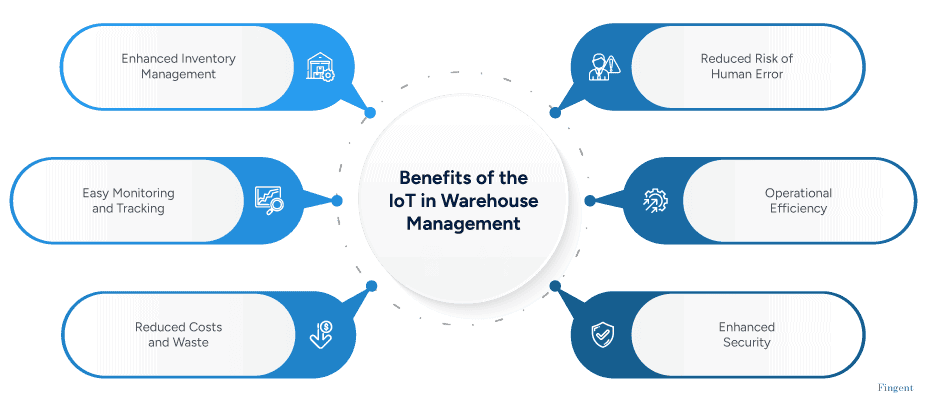

Benefits of the IoT in Warehouse Management

The industry’s growth rate shows that businesses are reaping the benefits of IoT in warehouse management. It is projected to grow at a CAGR of 13.1% from 2023 to 2030 and be worth USD 28.79 billion by 2030!

IoT-based warehouses, also known as smart warehouses, are making a notable difference. The IoT has plenty to offer, showing benefits ranging from increasing efficiency to cutting costs:

1. Smart Shelves: Enhanced Inventory Management

IoTfor inventory management enables comprehensive data analytics to check inventory levels. IoT-embedded shelves detect low inventory levels and send immediate restocking alerts. This ensures that stock levels are maintained efficiently.

IoT provides precise tracking of assets to cut the time to locate products. It also gives accurate insights into inventory flow management. These strategic decisions about stock replenishment and resource allocation can transform your warehouse.

2. All Eyes on Deck: Monitoring and Tracking

With Bluetooth connectivity, IoT can offer real-time monitoring and operation tracking. IoT sensors integrated inside inventory articles provide real-time updates to warehouse managers. They track product status, movements, and location. It also provides real-time data analysis and intelligent insights to optimize processes further.

IoT-based security cameras and sensors can oversee inventory shelves and storage areas. This ensures timely intervention and reduces the risk of stockouts or overstock. Real-time visibility can save resources, reduce waste, and prevent spoilage.

3. Waste Not Want Not: Reduced Costs and Waste.

IoT-enabled predictive maintenance systems can detect equipment malfunctions and send timely alerts to warehouse managers about proactive repairs, mitigating risks, and downtime. The IoT also enhances warehouse sustainability. With smart lighting and climate control systems, warehouses can reduce the energy they consume.

4. On Guard: Enhanced Security

With IoT sensors, warehouse managers can oversee asset movement and environmental conditions. This mitigates the risk of theft and accidents while ensuring product integrity. These sensors are designed to gather data and send real-time alerts, enabling swift and effective action.

5. Reduced Risk of Human Error: Operational Efficiency

The biggest benefit of implementing IoT is the removal of human error. This can exponentially increase operational efficiency. Automated systems can perform mundane tasks and lower the chances of mistakes. Hence, freeing employees to work on complex aspects of the warehouse.

Seamless integration of smart devices and sensors can streamline workflow and boost productivity. These devices can also communicate with each other in real-time. Automated guided vehicles (AGVs) and telematics reduce the need for manual intervention. Thus, boosting logistics processes’ speed and accuracy.

Elevate Your Warehouse Management Efficiency With New-age Technologies

Common Challenges of Implementing IoT in Warehouse Management and Ways to Overcome Them

IoT in warehouse management is a powerful tool that will be invaluable, there’s no doubt about that. What do you do to ensure that this tool works for you? The first step is to recognize and overcome the challenges that come with IoT in warehouse management.

1. Data Integration and Management

Challenge: Most organizations have diverse data streams. Integrating these databases without any complications can be challenging.

Solution: A comprehensive data management platform can resolve this problem. The platform can unify and normalize data for analysis. Ensure that clear data management policies are laid out to evade security risks.

2. Legacy System Integration

Challenge: This is the most common challenge among various industries implementing IoT. Many businesses have a legacy system that does not support IoT in warehouse management, further complicating the integration process.

Solution: An effective way to mitigate this issue is to use APIs and middleware solutions. They will provide seamless data exchange between IoT devices and legacy systems.

3. Interoperability

Challenge: Buying devices from different vendors can create problems, and seamless communication between these devices can be challenging.

Solution: Adhere to open standards and protocols when adopting an IoT solution. Conduct thorough testing before deployment to identify and address interoperability issues.

4. Cost Considerations

Challenge: Although IoT can help you save money in the long run, its initial implementation can be expensive. Ongoing maintenance of sensor networks, devices, and infrastructure can also be a cost.

Solution: The best way to address this challenge is to brace for impact. Before implementation, conduct a thorough cost-benefit analysis to note potential ROI. Browse through various rollouts or cloud-based solutions to manage costs effectively.

5. Data Security

Challenge: Most business owners are increasingly concerned about the security of their data integrity. Trusting a new solution based on the Internet can be daunting, especially regarding sensitive inventory and operations information.

Solution: Conduct a comprehensive background check on your service provider before employing them. Once the solution has been deployed, regular risk assessments will be conducted. Employee training in cybersecurity is also important. Your cybersecurity measures must include encryption and regular patching.

6. Change Management

Challenge: Change is inevitable, but that doesn’t exempt it from being condemned by many. Successful IoT implementation will require full support from the warehouse staff. This can be challenging, as some employees may not be tech-savvy.

Solution: Education is key. The best way to ensure a successful implementation is through open communication. Express the benefits of IoT solutions for warehouse management and highlight how they will enhance productivity and security. Provide adequate training to all employees in IoT technology, software, and processes. Begin with small-scale pilot projects before implementing full-scale rollouts.

How Does Amazon Use IoT in Warehouse Management?

Unsurprisingly, the world’s largest retail business uses IoT in its warehouse management system. Amazon uses sensors, and it is commonplace to see robots manage tasks like packing, stocking, and tracking. It has used automated guided vehicles to transport products within the warehouse for over a decade. Here are some other ways Amazon uses IoT in its warehouse:

- Robots: Amazon uses 100,000 robots to move and group stock, taking shelves with items to the picking and packing zone and then moving them to the storage area. This helps to create efficiencies in order fulfillment and eliminate the physical rigors of an otherwise physically demanding job.

- RFID tags: These tags are attached to products. Radio waves communicate data about the product to a central system. The data includes information about the asset’s location, type, and quantity. This allows warehouse managers to track the asset without relying on manual input from staff.

- Connected wristbands: Amazon is considering using connected wristbands on a whole new level. Ultrasonic tracking can detect a worker’s location. A haptic feedback system takes it a step further. Vibrations will nudge the worker’s hand in the right direction. Imagine the reduction in response time this would mean!

Some Frequently Asked Questions Around the Use of IoT in Warehouse Efficiency

1. How does the IoT transform warehouse management?

IoT in warehouse management can enhance operational efficiency. It provides seamless integration of smart devices and sensors, which streamlines workflow. Thus, it enhances overall productivity and reduces the risk of human error.

2. What IoT sensors can be used in the warehouse?

The IoT sensors that are usually used in warehouses are:

- Sensors to Locate and track products

- Traffic light systems to reduce clashes and damage

- Dock and door motion monitors

- Sensors to prevent corner collisions

- Sensors to send alerts when stock is low

3. How can IoT improve the logistics process?

IoT in warehouse management can improve logistics processes through real-time tracking. It enables a dynamic real-time monitoring of shipments and assets, enhancing route management and delivery accuracy.

4. What are the benefits of IoT in logistics and warehouse management?

The benefits of implementing the IoT in warehouse management are multifaceted. They range from a streamlined flow of goods and reduced errors to increased visibility in inventory levels.

5. What industries benefit most from IoT in warehouse management?

Retail, e-commerce, manufacturing, logistics, pharmaceuticals, and the food and beverage industries benefit the most from IoT in warehouse management. These industries tend to have complicated supply chains and large inventories. Hence, IoT can provide the greatest efficiency, accuracy, and cost savings advantage.

Reduce Labor Costs With Warehouse Automation

How Can Fingent Help Bring Warehouse Efficiency to New-Age Technology?

Implementing the IoT in warehouse management requires a deep knowledge of the technology and an innate sense of how it can work for your business. Fingent is a service provider with clients across the world. We offer vast and extensive experience in delivering highly intuitive applications and solutions. Our experts can add immense value to your strategy and make seamless deployments. We can make your processes efficient, cut excessive costs, and unlock hidden potential.

We understand the need to implement the latest advancements in warehouse management systems. A case in point is the web-based solution that we recently provided for one of our clients in Australia. The solution helped the client to track, control, and efficiently manage deliveries. This resulted in

- 43% increase in customer base

- 50% reduction of internal workload.

Fingent has helped leading businesses create product ordering systems, e-commerce applications, and more to enable optimized operations. We help organizations adopt cutting-edge technology while gradually replacing legacy systems, enabling them a competitive edge!

Take customer satisfaction to another level with us! Contact us now!

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

The warehouse is the beating heart of the organization. With goods moving in and out consistently, any mishap can create a domino effect that can impact the entire company’s performance. How do you ensure that your warehouse operations are shipshape? An efficient warehouse management system is the answer! However, identifying a suitable solution from the available types of warehouse management systems can be tricky.

A proper warehouse management system can help improve order fulfillment, enable your team to be more responsive in real-time, and strengthen your supply chain. Over 83% of warehousing and logistics providers already use WMS. Which warehouse management system is best for you, though? This article will explore the world of WMS and highlight the significance of each type of system so you can make an informed decision.

What is a Warehouse Management System?

A warehouse management system is software that improves warehouse operations. It automates and streamlines processes enhances productivity, eradicates error risks, and creates a well-planned layout. These system applications play a key role in supply chain management. They offer real-time analysis and tracking and provide data filtering for key performance indicator (KPI) analysis.

A subpart of warehouse management systems is inventory management systems. As the name suggests, these applications handle warehouse inventory. They contribute to optimizing supply chain management. They provide inventory control, thus mitigating risks of inventory overstocking, pilferage, and wastage. All these functions will improve customer service and boost profitability.

Let Us Help You Identify The Right Warehouse Management Solution For Your Business

How Many Types of Warehouse Management Systems Are There in the Market?

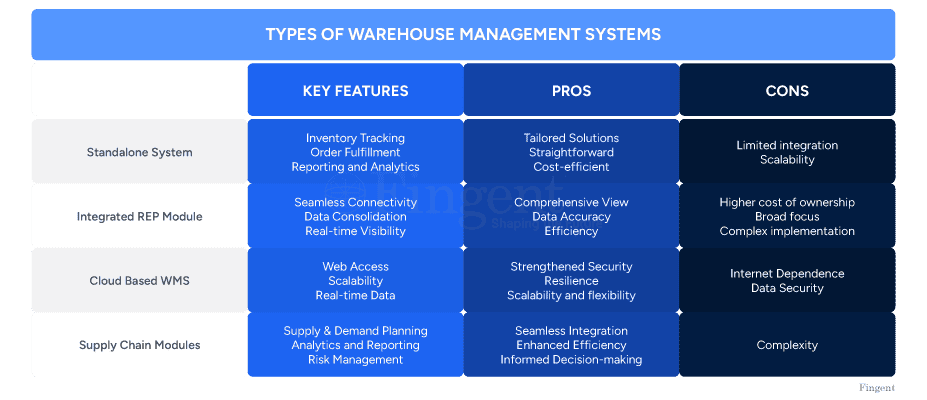

Different businesses require different functions from their warehouse management system. Four types of warehouse management systems cater to these businesses’ unique needs: Standalone, ERP Module, Cloud-Based, and Supply Chain Module. Each of these applications has its benefits. They differ in integration capabilities and suitability for various business sizes. Understanding the key differences between these systems is important before you choose.

What Are the Key Types of Warehouse Management Systems Available?

Let’s take a close look at the four primary types of WMS systems and their key features, benefits, and drawbacks.

1. Standalone System

Standalone WMS is a software solution designed for small and medium-sized businesses. It offers cost-effective management that organizations with a tight budget can benefit from. This system application provides a focused approach without extra integration with other systems.

Key features:

- Inventory tracking: Provides detailed visibility into warehouse stock levels, locations, and undertakings. Additionally, it also offers barcode scanning, RFID tracking, and real-time inventory updates

- Order fulfillment: It optimizes order processing, picking, packing, and shipping. Other features include automated pick lists, packing slip generation, and real-time shipment tracking.

- Reporting and analytics: It automatically generates reports on inventory movement, order accuracy, and warehouse performance. These reports undergo analytics that provide insight into improvement with visualization tools.

Benefits:

- Tailored solutions: These solutions are designed specifically for warehouse operations and provide advanced features customized to your organization’s unique needs.

- Straightforward: Since it is not linked to any other business software, it comes with fewer complications. The steps involved in setup and maintenance are simple and run in a shorter time frame.

- Cost-efficient: This solution focuses on a set approach without extensive integration with other systems, making it affordable for small—to medium-scale businesses.

Drawbacks:

- Limited integration: Since it doesn’t integrate into other business systems, it has restricted functionality.

- Scalability: This system doesn’t offer easy scalability due to its limited integration.

2. Integrated REP Module

Enterprise resource planning (ERP) software tracks and organizes business resources. This ERP module is often integrated with HR software systems and CRM solutions. It is suitable for businesses of all sizes and fulfills many client requirements.

Key features:

- Associated with enterprise resource planning system: It provides seamless connectivity between warehouse management and other business functions. It efficiently bridges the accounting, procurement, and customer relationship management gap.

- Data consolidation: The module oversees and synchronizes the centralization of business data. Furthermore, it provides up-to-date insights into inventory activity and warehouse operation, enhancing decision-making, operational efficiency, and productivity.

- Real-time visibility: The ERP module offers comprehensive visibility into business operations, from procurement to order shipment and financial reporting.

Benefits:

- Comprehensive view: Since it centralizes business data, there is a single source of truth. It mitigates the risk of any misconceptions across various departments in an organization.

- Data accuracy: It streamlines integration with various business functions. This way, data inconsistencies are removed.

- Efficiency: Streamlining is its strongest feature. By automating data transfers and process handoffs, it simplifies workflow.

Drawbacks:

- Higher cost of ownership: Implementation will include installing software and integration services. The initial investment and ongoing maintenance cost can strain resources, so it is not very popular among smaller businesses with simpler warehouse operations.

- Broad focus: It may neglect some specific management features due to its broad approach.

- Complex implementation: The implementation process can often be complicated and time-consuming. It also requires a great deal of resources that most businesses lack. Another major drawback is its lack of flexibility since customizations cannot be fit within the broader ERP system.

3. Cloud Based WMS

As the name suggests, this solution is web-based. It follows a centralized approach based on cloud technology. This type of WMS is popular for its scalability and deployment speed. It can provide speedy chain execution at cheap inventory expenses. The application does not need extensive installation or assimilation with legacy hardware or networks. It is the perfect pick for any business, big or small!

Key features:

- Web access: Since it is web-based, it can be accessed anywhere.

- Scalability: This solution is capable of scaling itself according to the business. It can also adjust resources based on demand and business needs.

- Real-time data: The cloud-based WMS provides real-time inventory and warehouse operations updates. Due to its web-based nature, it also provides mobile access.

Benefits:

- Strengthened security: Cloud-based WMS deploys many safety measures to keep data safe, including encryption, access controls, and security audits.

- Resilience: This solution is immensely resilient to connectivity issues. It is designed to maintain functionality even when the internet connection staggers. When the internet connection is restored, local caching and data synchronization are conducted automatically.

- Scalability and flexibility: The solution allows businesses to adjust their software usage based on business needs. Thus, users only pay for their services, saving extra costs.

Drawbacks:

- Internet dependence: Despite quickly recovering from internet connection cuts, they can disrupt access and operations.

- Data security: Privacy and security are unspoken risks with web-based systems. Businesses are at risk of security breaches, and confidential data stored on external servers is at the most risk.

Read more: Warehouse Management System:Business Applications & Case Studies

4. Supply Chain Modules

These modules focus solely on supply chain management. They automate the monitoring of inventory restocking, material procurement, and other mundane tasks. This technology helps customers manage various aspects of supply chain visibility.

Key features:

- Supply and demand planning: It can predict future demand based on historical data, trends, and market analysis. Hence, it ensures optimal stock levels in the warehouse. It also manages supplier relationships and purchase orders to coordinate for timely supply.

- Analytics and reporting: These modules can track key performance indicators (KPIs) and provide reports for insights into supply chain performance.

- Risk management: It can identify and perform regular risk analysis tests. It also develops contingency plans and strategies to mitigate the disruption.

Benefits:

- Seamless integration: It can easily assimilate with other supply chain software applications, allowing for smooth data sharing and real-time visibility within warehouse operations.

- Enhanced efficiency: It optimizes warehouse processes and reduces inefficiencies, leading to cost savings and a faster response time frame.

- Informed decision-making: This system analyzes data in real-time and helps make informed decisions and forecast demand.

Drawbacks:

- Complexity: One of the main disadvantages of this WMS is that it requires extreme customization and extensive integration with other systems. This leads to higher costs and can be complex for beginners to understand.

Why Does Your Business Need To Build A Modern Warehouse Management System?

Frequently Asked Questions about Warehouse Management Systems

1. Why is a Warehouse Management System important for businesses?

Implementing a WMS enhances organizational efficiency. It automates and streamlines warehouse processes, improving inventory accuracy, reducing operational costs, and enhancing customer service. It also provides real-time analysis of inventory and warehouse operations.

2. What are the key features of a WMS?

- Inventory Management: It tracks stock levels, locations, and warehouse movements.

- Order Fulfillment: It can handle product picking, packing, and shipping processes.

- Labor Management: It optimizes workforce productivity by automating mundane tasks.

- Reporting and Analytics: It can run analytics and provide insights into warehouse performance.

3. What are the costs associated with implementing a WMS?

The cost of investing in a warehouse management system depends on your business size. Factors such as operational complexity and on-premises or cloud-based solutions play a key role. The expenses often include software licenses, hardware, implementation services, and ongoing support.

4. What are the latest trends in WMS technology?

- AI and Machine Learning: AI enhances decision making and ML provides predictive analytics.

- Automation and Robotics: Automation increases efficiency, and robotics mitigate the risk of errors.

- Internet of Things (IoT): The IoT improves real-time tracking and monitoring of assets.

- Mobile Solutions: It promotes remote access and offers flexibility for warehouse managers.

5. What challenges might businesses face during WMS implementation?

The most common challenge is staff resistance to change. Other challenges include data migration issues and integration with existing systems. Appropriate planning, training, and change management strategies can help curb these challenges.

Why Choose to Build a Custom Warehouse Management System?

Irrespective of the types of warehouse management systems you choose, buying a custom one is the best decision for a company. It offers several advantages, such as a uniquely tailored solution, scalability, and flexibility. These systems sync your business’s processes, ensuring seamless integration with existing operations. The unique solution will allow for better alignment with specific workflows.

Custom WMS also provides flexibility and scalability. With these systems, you can opt to grow and evolve. This adaptability is valuable for companies with intricate or specialized needs. With a custom WMS, you have ultimate data security and compliance control. This becomes crucial when dealing with sensitive information. A custom solution can be more expensive than off-the-shelf software. Yet, it provides a better return on investment by enhancing operational efficiency.

How Can Fingent Help?

At Fingent, we understand your goal to ensure the right products are delivered on time. We specialize in helping leading logistics and supply chain companies leverage new-age technologies for effective warehouse management and operations. Our custom solutions are crafted to cater to warehouse management’s unique needs and challenges.

Tap into our expertise to develop the best custom WMS for our clients. Our in-depth experience in B2B e-commerce applications, product ordering systems, and self-service payment portals has helped clients worldwide gain a competitive edge.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Robots in Warehouses – the extremely successful blockbuster that is proving to be a reality in the world of warehousing! Warehouse automation is combating rising labor costs, smoothing out processes to improve efficiency, and even saving lives by reducing errors that cause accidents.

The global warehouse automation market is expected to grow at a CAGR of about 15% and reach 41 billion U.S. dollars in 2027. It looks like the whole world of warehousing is ready to be automated. Are you? This blog will help you explore how you can use the power of Robotic Process Automation and Artificial Intelligence in your warehouses to transform your business.

What Is Warehouse Automation?

Warehouse automation is the process of automating the operations inside a warehouse. It uses advanced technologies to streamline operations, which can range from processing information on inventory to transportation in and out of the building. Warehouse automation solutions aim to perform all in-house tasks with minimal human interference. Some of its benefits include reduced errors, enhanced customer satisfaction, and robust productivity.

As of 2023, the global warehouse automation market was valued at over 23 billion dollars. Evidently businesses are recognizing the potential of this power tool.

As part of an automation project, a company can start with a warehouse management system (WMS). This system assists with data collection and inventory control. It eliminates the need for manual labor for repetitive tasks. It also removes the risk of human error while adding the perk of automated analysis. The future of warehouse automation is enhanced with the accompaniment of robotics. Integrating artificial intelligence into the warehouse environment creates a symphony that will only rise in crescendo over the next few years.

Learn More About Warehouse Management System. It’s Business Applications & Use Cases.

What Are the Different Categories of Warehouse Automation?

Warehouse automation runs against the backdrop of various technologies. It can help you increase productivity and mitigate challenges. Gartner conducted a study on the adaptation of automation in warehouses. They concluded that by 2027, over 75% of businesses would install cyber-physical automation.

However, this isn’t a one-size-fits-all approach. There are different categories of warehouse automation that you need to be familiar with. Here are the most popular types of warehouse automation:

1. Goods-to-Person (G2P)

This type of automation directly delivers goods to warehouse operators. They are transported through carousels, vertical lift modules, and conveyor belts. This facet of warehouse automation enhances efficiency and productivity while reducing inventory congestion. G2P also reduces the risk of errors during the picking and packing processes. It is cost-effective and saves time.

2. Automated Storage and Retrieval Systems (AS/RS)

An AS/RS system automatically stores and retrieves goods from defined storage locations with impeccable accuracy and speed. This category of warehouse automation is ideal for manufacturing and distributing industries. AS/RS saves floor space, improves safety, and enhances productivity. It can range from unit-load systems to mini-load systems. Unit-load systems handle large goods, while mini-load systems manage smaller goods. There is also a third range called the micro-load system. These warehouse automation solutions are designed to handle very small and intricate goods.

3. Mobile Robots

Automated mobile robots (AMR) use AI to navigate the warehouse. They move without the need for human help and primarily transport goods. Automatic Guided Vehicles (AGV) are another type of mobile robot. They can transport goods over longer distances than AMR. Their main drawback is that they need guidance from warehouse operators. They are also not integrated with AI, and so they rely on wires and reflective markers.

4. Automated Dimensioning Systems

These systems are designed to scan and analyze the physical details of goods. They use infrared, camera, weighing, and barcode technology. There are two types of dimensioning systems in an automated warehouse:

- Automated Parcel Dimensioning Systems: This system is designed to capture the dimensions, weight, and images of a 3D parcel in seconds. It can automate the parcel dimensioning process and eliminate any human error.

- Automated Pallet Dimensioning System: This system is designed to capture the dimensions, weights, and images of pallets. It is designed to measure in cubic inches. It can also measure irregular-shaped pallets.

5. Pick and put to light systems

These systems are laced with order-fulfillment technology. They used colored LED lights as guides for operators. These lights guide warehouse operators to the correct location to pick, sort, and place items.

6. Drones

These are the most advanced types of warehouse robotics, also known as Unmanned Aerial Vehicles (UAVs). These advanced flying devices use optical sensors, infrared cameras, RFID technology, and more. They can locate cargo and conduct inventory counts, among other functions. Drones can also send orders to warehouse managers if any item is in the wrong storage location. They are highly functional, as they can reach even the innermost space inside a warehouse.

7. Automated Sortation Systems

These technological systems are designed to handle goods in a warehouse environment. Once they identify goods on the conveyor system, they direct them to their respective storage locations. These systems use barcode scanners, radio frequency identification (RFID), and sensors. They perform the tasks of receiving, picking, and packing.

How Does Automation Help Warehouses?

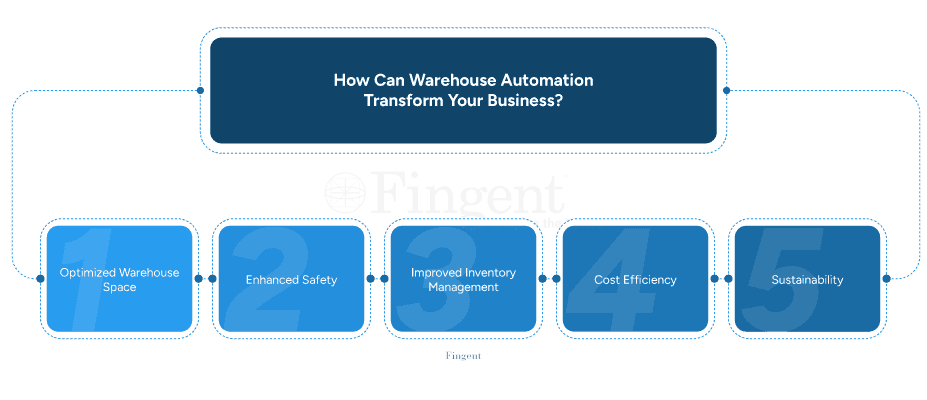

Warehouse automation is the most integral step in supply chain optimization. It reduces time, effort, and errors, which ultimately enhances efficiency. The benefits of automating your warehouse are multifold. Listed below are some of the major benefits you gain from this venture.

1. Optimization of Warehouse Space

Warehouse automation systems maximize warehouse foot space. Since they use warehouse-automated robots to perform tasks, used space is significantly reduced. By using conveyors and lifts, AS/RS systems reduce the amount of space used for aisles. This increases the number of shelves where goods can be stored. Investing in warehouse robotics can clear out most of your warehouse space and allow you to optimize your space.

2. Enhanced Safety

Automated warehouses can prevent workspace injuries. Since these systems perform all the heavy lifting tasks, they protect warehouse employees. Foot and equipment traffic throughout the warehouse also decreases. This further enhances safety and efficiency. Warehouse automation systems also reduce product damage as manual handling of the goods is reduced.

3. Improved Inventory Management

Balancing supply and demand has become a complex task due to unstable supply chains. Automated warehouse systems can help here. They come with a portfolio of benefits, and inventory management is their strongest suit. These systems can prevent backlogs, adapt to fluctuations, and enable just-in-time production. Logistics automation systems are designed to track information about specific inventory products. The data is then displayed on demand, making it easy to analyze for information. This system can also send large volumes of data to managers. It fosters accurate communication and more informed decisions.

4. Cost Effectiveness

Yes, the initial investment in the automation of warehouses can be an expensive affair. Yet, its long-term cost reduction benefits more than makeup for it. An impressive quick ROI is that warehouse automation offers new points of cost-cutting. It removes the need for repair costs due to mishaps in handling goods. Because of the AS/RS system, there is more foot space in the warehouse. This means it has increased capacity to hold more goods. Minimizing inventory errors and workflow errors also aids in cost-effectiveness. With warehouse automation robots, there is less need for staff administration and training costs.

5. Sustainability

While cost advantages are an obvious benefit, long-term sustainability is a big perk of warehouse automation. Automation adds sustainability to your warehouse operations. The automation modules remain in standby mode when not in use, preventing them from consuming unnecessary energy, which in turn reduces the operational carbon footprint. By improving accuracy, the warehouse generates less waste. All these factors lower energy costs and improve resource efficiency.

Not Sure How To Start Your Warehouse Automation Journey?

What Are the Top Warehouse Automation Technology Trends?

As the year passes, warehouse automation has gained more popularity. Here are some of the top trends for 2024.

1. Artificial Intelligence and Machine Learning

Artificial Intelligence(AI) is the ability of a computer or robot to mimic human cognition. It boosts productivity and enhances accuracy within the warehouse environment. It can also automate various tasks to prevent any risk of human error. Thus, floor workers can focus on more complex tasks and leave the mundane jobs to AI.

Machine learning is a type of AI that enables machines to read and recognize patterns. ML can analyze previous activities and make accurate predictions. It is used to perform tasks such as inventory planning and stock forecasting. Robots powered by ML are designed to handle fragile products to cut the risk of damage.

2. Collaborative Robots

Also known as Cobotics, these instruments combine humans and robots. They are designed to assist people but do not replace human tasks. Cobots within a warehouse include Autonomous Maneuverable Robots. These are human-operated machinery used to recognize changes within the warehouse. They also have a 360-degree field of vision and can safely drive in reverse when needed.

3. Internet of Things

RFID tags and wearable devices continue to take the market by storm. They carry new IoT applications that have the ability to streamline warehouse operations. IoT widens warehouse automation by adding a layer of technological advancement. It can provide location data on any goods and report inventory details in real-time. It can also track, manage, and monitor equipment inventory. IoT sensors provide enhanced data collection methods across various departments and systems.

4. AR/VR

Virtual reality is a computer-generated simulation that mirrors reality accurately. It is interlaced with neural networks, ML technologies, and AI. VR can create an immersive experience within the warehouse tracking system. Augmented reality is a branch of AI that combines real-world experience with a computer-generated world. This makes it a highly interactive form of Artificial Intelligence. Virtual Reality and Augmented Reality can be integrated into your automated warehouse environment. They can increase employee morale, work efficiency, and safety. For instance, managers can use a 360 VR headset to address warehouse operations. Employees can familiarize themselves with the warehouse even before actually entering it.

5. ERP Integration

Application programming interfaces and ML are two driving factors in an automation system. They are integrated into an ERP system to create an enhanced business platform. Advancements in automation and ERP applications will improve workflow. They will also invoke creativity and customer-centered tasks.

6. Wireless Fleet Management

Innovations like IoT, cloud databases, and sensor technology create wireless automated fleet vehicles. These systems are designed to handle tasks of compliance and maintenance. They also track driver performance and vehicle maintenance.

7. Voice Recognition

This is an emerging automation technology that can recognize voices. It receives information in the form of commands. In voice-picking, employees are required to wear a headset to deliver commands. They can prompt instructions to lead them to the picking location. This technology can boost picking accuracy and efficiency within a warehouse.

8. Generative AI

This branch of AI creates, analyzes, and generates data for logistics optimization. It manages tasks such as risk management, demand forecasting, and warehouse layout design. It can also handle inventory management, route optimization, and customer service automation. Generative AI is also backed by advanced modules like predictive analytics. Thus, it is anticipated to be the next big thing in the supply chain landscape.

Cloud Data Warehouse: A Definitive Guide For Your Business

When Should You Automate Your Warehouse?

Warehouse automation solutions are widely popular for their ability to cut costs. Just like any other investment, this technology can be initially expensive. Yet, it is extremely beneficial in the long run. If manual labor can no longer meet business needs, warehouse automation is the solution. The world of business and supply chains is cutthroat and ever-evolving. You must adapt to these changes if you want to stay in the competition. To help you understand this concept better, here are a few clear signs that you need to automate your warehouse.

- Manual labor is causing too many mistakes and inefficiencies.

- Your inventory management is faulty.

- You are running low on storage in the warehouse.

- There have been too many safety issues and risks.

- You are financially running low and want to cut back on labor costs.

- Business is booming, and you are required to handle larger volumes of shipments.

- You need to boost employee morale and productivity.

- Customer satisfaction feedback is low.

What Warehouse Processes Can Be Automated?

According to a study, warehouse automation can reduce costs by up to 40%. It is also expected to enhance productivity by 25% to 70% by 2025. Business owners are not overlooking the benefits of warehouse automation. As of 2030, predictions say that the global warehouse automation market will grow and surpass $37.6 billion.

How are businesses achieving this, and what are they automating?

Listed below are some warehouse operations that have already been implemented by businesses:

1. Barcode Scanning

Every product has a unique barcode that separates it from other products, simplifying the process of looking for them. Employees have to look through the picking list to find the product. When it’s shipping time, they can find the product’s location using the automated barcode scanner. Once it is located, the scanner also provides automated routes for efficiency.

Case in point: Amazon

Amazon uses automated barcode scanners and is considering introducing multimodal identification, or MMID. This might eliminate the barcode process itself and bring in complete robotic identification based on a product’s appearance and dimensions. No wonder Amazon is the most dominant online retail store with the most optimized warehouse.

2. GTP (goods-to-person) Systems

The automated goods-to-person system is a picking system that uses autonomous robots. These bots carry packages loaded on the shelves to warehouse workers for order fulfillment.

Case in point: Nike

Nike has implemented this technology to transform its logistics and customer satisfaction. Nearly 200 robots have been used to design this new distribution system, which provides same-day delivery to customers.

3. IKEA and Tadim: AS/RS Systems

AS/RS distribution systems are designed to automate the segregation and storage of goods. These systems play a key role in inventory systems and equipment management.

Case in Point: IKEA and Tadim

IKEA has the most intricate warehouse automation system worldwide. It includes 100-foot-tall trilateral stacker cranes and conveyor rack systems, which are designed to transfer 600 pallets to shipping areas within an hour!

Tadim, a nuts and dried fruit retailer in Turkey, also enjoys the benefits of the conveyor system. Their warehouse receives around 1000 pallets a day. The conveyors optimize the flow of goods and reduce the risk of accidents.

4. Warehouse Management System

Back-office tasks are the most mundane projects in a warehouse. They are also very important, so businesses cannot afford to make mistakes. Digital process automation can help optimize back-office operations.

Case in point: DHL Supply Chain

DHL, a leading contract logistics provider, has implemented an AI powered Warehouse Management System to more than 2,000 sites worldwide. The system has streamlined customer-specific processing, improved integration between warehouses, and enhanced multi-level order processing.

How Much Does It Cost to Automate Your Warehouse?

Warehouse automation can be an expensive affair in its initial stages. It uses robotic technology and AI-powered software applications, which are inherently expensive. Nonetheless, warehouse automation is one of the best investments a business can make. It is worth every penny spent and will be paid back, especially for retail companies. Some basic estimates for a warehouse automation project, according to 6 River Systems, a leading fulfillment solutions provider, are:

- An effective picking system will cost between $500,000 and $1 million.

- A fully equipped mechanized operation system will cost between $1 million and $5 million.

- Transitioning to a semi-automated warehouse will range from $5 million to $15 million in costs.

- Implementing a fully automated warehouse will cost no more than $25 million.

The decision to convert a manual warehouse to an automated warehouse should be well-considered. First, analyze your business’s current financial status and modify your budget. Below is a concise checklist before you invest in an automated warehouse.

- First, calculate your company’s current estimated ROI.

- Second, analyze the budget for your current warehouse operations. This will include labor costs, equipment management costs, and any annual increases.

- Next, determine your average rate of turnover for warehouse employees. Remember to include the cost of hiring and training the new employees.

- Next, research and estimate the purchase cost of a new automated system. Include the cost of labor and cost savings. Factor in the cost of training, implementation, and maintenance.

- Lastly, compare these figures. This will help you determine the estimated minimum ROI for warehouse automation.

Leveraging Warehouse Automation with Fingent

Fingent is a world-class solution provider. Here, you will receive the best technology solutions with the highest level of professionalism. We have in-depth experience developing various bespoke software applications, from B2B e-commerce applications to tailored self-service payment portals.

We are trusted by many organizations, including Fortune 500 companies. Using our expertise, we can help you build a custom WMS tailored to your unique business needs. Our custom-built applications aim to enhance logistics, shipping, transportation, and more, taking your company to the future!

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Maximize productivity and minimize uncertainty! That’s what Artificial Intelligence promises the Supply Chain and Logistics industry. The fragility of the supply chain is not unknown to industries. Delays, stoppages, and complexities in the supply chain are a few limitations businesses are striving to overcome. Operational efficiency, intelligent decision-making, and continuous improvement must be maximized. Thankfully, AI helps do just that. This blog will take you through the top benefits businesses can derive with AI in Supply Chain!

Why Is Now the Best Time for Supply Chain and Logistic Firms to Adopt AI?

The global trade scene and geopolitical risks have not been kind to the supply chain. A 2023 Annual Supply Chain Report revealed that events around the world continue to have a detrimental impact on it. These include political upheavals, climate-related events, supply chain legislation, and more. Internally, there are issues to deal with as well. A lack of governance and data management, labor strikes, and communication hurdles have proved challenging.

Not everything is bad news, though. These harsh conditions have built resilience and determination in supply chain and logistics organizations worldwide. A 2024 KPMG study of supply chain trends says: “Enabled with a raft of technology developments, a new paradigm is emerging in supply chain management. One where organizations can respond quicker to day-to-day requests, proactively address problem-solving, and reduce errors and inefficiencies.”

Businesses are becoming wise to the situation and are reaping benefits. According to a McKinsey report, leveraging AI has helped businesses enhance logistics costs by 15%.

AI helps companies gain a unique competitive advantage in supply chain management and logistics operations. It can install advanced algorithms and large-scale data analytics as an emerging technology. This simplifies supply chain workflows and boosts decision-making processes. Some other perks of leveraging AI-powered technologies are accurate forecasting, inventory management, optimization of transportation functions, improvement of flexibility and agility, and enhancement of customer satisfaction. These are all the ingredients you need to get your supply chain processes back on track.

The time to build resilience with the help of technology is NOW!

Explore More Business Opportunities With Artificial Intelligence

What Are the Top Benefits of Using AI in the Supply Chain?

AI can bring operational efficiency, on-time delivery, accurate predictions, risk management, and more to the supply chain and logistics management. Here are the top benefits industries can reap by deploying AI for logistics.

1. Reduced Cost

AI has the power to automate tasks. This gives a power boost to the human workforce. . It frees them up for higher-value activities and takes over the burden of mundane labor. This optimization of labor practices will reduce labor costs while increasing efficiency. AI-powered forecasting can help maintain optimal inventory levels, decreasing any risk of stock-outs and loss of sales. This directly contributes towards cost savings

2. On-Time Delivery

AI systems can process large amounts of data in real time. It can recognize patterns, enhance inventory levels, and accurately predict demand. This predictive ability ensures on-time delivery, thus enhancing operational efficiency. Generative AI can use algorithms to analyze transportation routes and optimize logistics scheduling. This will, in turn, improve delivery times and reduce fuel consumption and transportation costs. Another major benefit is real-time tracking and updates on orders. This provides transparency with customers that will increase their confidence and satisfaction.

3. Accurate Management And Planning

Predicting future demands is vital for effective stock and product management. AI algorithms can forecast product demand for specific seasons of the year. This enables companies to make well-informed decisions about managing inventory. As for logistics firms, AI can enhance supply planning. By analyzing factors such as production schedules, sales data, and costs. This analysis helps businesses to plan warehouse functions. This includes managing stock levels and surplus inventory. Thus reducing costs and providing control over expenses. A survey by McKinsey showed a reduced cost expense of 15% in logistics management. Early adopters of AI-powered supply chain management saw this change.

4. Risk Management

Leveraging AI for supply chain management and logistic operations can reduce risk. AI bots can be used effectively in this regard. They do this with the application of advanced analytics and scenario modeling. This enables businesses to create complex contingency plans and adapt risk mitigation strategies. Generative AI measures the impact of any chain of damage. This will, in turn, allow companies to respond and use effective mitigation strategies. AI-powered supply chain monitoring tools work together to identify any risks. Early detection alarms, for example, enable timely intervention and reduce impact on performance.

AI Use Cases In Logistics

Artificial Intelligence controls data and uses machine learning to optimize the flow of goods. With algorithms to identify patterns, relationships, and trends, AI enables accurate predictions and recommendations. Here are some use cases to show how this can help businesses:

1. Bullwhip Effect Prevention

A small change in demand can create catastrophic ripples across the supply chain. Effective demand forecasting helps mitigate this bullwhip effect. Demand forecasting utilizes predictive analytics to estimate customer demand forecasts. It does this by analyzing historical data in real-time. With this method, businesses can improve their decision-making processes and workforce planning. Thus, AI-powered demand forecasting can reduce error rates, leading to improved accuracy in demand prediction. Manufacturers can manage every little detail, like the number of vehicles dispatched, and thus reduce operational costs.

According to a Gartner study, demand forecasting is the most used ML application in supply chain planning. The study also highlighted that 45% of businesses have already implemented this technology, and 43% plan to use it within the next two years.

2. Automation Warehousing

Reports estimate the warehouse robotics market will reach USD 10.5 billion by 2028, accompanied by a CAGR of 11.4% during the forecasting period. The need for operational quality is the fueling force that drives this growth. Amazon is a great example of this change. The giant retail company Amazon has close to 200,000 robots functioning in its warehouses. These robots help employees pick, sort, transport, and stow packages.

Computer vision technology allows businesses to identify damaged goods. This ensures quality control in warehouse operations. Logistics managers can also regulate the size and type of damage. This will help them take appropriate action. Predictive maintenance is another technology that is very beneficial to a company warehouse. It can predict machine failures in the factory. It does this by processing real-time data gathered from the IoT sensors.

3. Back Office Management

Every company has a back office that handles the brunt of the workflow. It manages largely repetitive tasks, including bill of lading, invoice maintenance, document processing, and customer services. AI can transform these processes into simpler tasks.

An example is the invoice of rate sheet documents. They manage communication within the workspace. With the help of AI, this process can be automated and made efficient. Accurate data input, error reconciliation, and document processing make this possible. Hyperautomation can help here as well. It combines Artificial Intelligence with robotic process automation and process mining. Together, they make the automation process seamless.

Customer service chatbots analyze customer experience with chatbot analytics metrics. This helps them understand the customer’s needs and respond accordingly, leading to higher customer satisfaction rates.

4. Sales & Marketing

Predictive lead scoring is a subfield of AI and is invaluable to the sales function. It uses machine learning to calculate a score for open leads based on historical data. Lead scoring will ensure that sales reps can focus on the right prospects for the company. This AI-powered tool can assign appropriate scores to leads based on their profile, behavior, and interests. These algorithms can process data. Thus, they can predict which leads will convert into paying customers.

AI can also analyze sales and marketing. With the help of AI-powered tools, logistics service providers can process customer behaviors. This helps them predict the customer’s next move. They can also track fluctuations in the market, enabling logistics service providers to be alert and make data-driven decisions.

Reshape Customer Experiences with AI & ML

What Are the Top Trends in AI for Supply Chain?

IoT, Hyper-Personalization, Robotics, and Natural Language Processing are some of the top trends businesses can expect to see and implement going forward. Here are the details:

1. Better Integration With The Internet Of Things (IoT)

Internet of Things (IoT) devices allow for real-time tracking of products in a supply chain. When combined with advanced AI technology, they can perform a wide range of tasks. These tasks include optimization of routes, reducing delays, and enhancing supply chain management.

New technologies, such as digital twins, will allow companies to develop a digital model of the product. This can help companies create a virtual representation of their supply chain model. Drones are also equipped with IoT sensors to test deliveries. Studies estimate that around 70% of urban deliveries are drone-based package delivery networks.

2. Autonomous Supply Chain Systems And Robotics

A 2023 Gartner study predicts that 75% of companies will install cyber-physical automation in their warehouse operations by 2027. The use of robotics and AI-driven systems will streamline the warehouse processes, thus reducing reliance on labor and resources.

Some companies, like Amazon, have already installed autonomous mobile robots (AMRs). In the future, many more companies will follow suit, and we can expect to see AMR technology bloom. These autonomous robots will have systems working 24/7, thus implementing a higher level of quality and productivity.

3. AI-Driven Hyper-Personalization Of Service

The increased priority to customer service is a trend seen throughout innumerable industries. AI can help with this by analyzing customer data and preferences. Businesses can better curate their services to personalized needs. With the introduction of AI, hyper-personalization will grow further. It will encourage manufacturing managers to leverage Machine learning. This will automate manufacturing adjustments that will, in turn, improve customer experience. According to reports, AI-driven forecasting can improve supply chain resilience. It has the potential to reduce stockouts by 50%.

4. Adoption Of Advanced AI Technologies (NLP, Annss)

More and more companies will recognize the potential of high-level AI systems. They will rely on Machine Learning, deep learning, and natural language processing. We will see a rise in data analytics quality and, by extension, better decision-making.

Machine Language has an unparalleled ability to process large amounts of data to recognize trends. It will improve accuracy when it intercedes with forecasting inventory needs.

Artificial Neural Networks (ANNSs) are subfields of AI that use deep learning and ML. They detect anomalies and predictive maintenance needs. NPL will also play a big role in enhancing workflow. Thus improving communication between team members, employees, and machines.

How Can Fingent Help Future-Proof Your Supply Chain And Logistics Firms With AI?

At Fingent, we recognize and understand AI’s transformative power. We expertly maneuver its ability to optimize your supply chain and offer curated custom logistics software development services. Experts at Fingent understand what is needed to implement AI solutions effectively for your business. They specialize in AI technologies like Machine Learning, Natural Language Processing, and Robotic Process Automation. We can thus help you tap into the latest advancements in technology.

When you work with Fingent, you get a dedicated team of experienced professionals who can guide you with expertise in logistics management and advanced AI services. Connect with us today to develop customized solutions for streamlined operations, seamless processes, and competitive advantage.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Cost, Compliance, Efficiency, and Manpower – These are the pillars on which a fleet management business stands. A compromise on any of these can mean the whole business topples with a resounding crash.

How can you ensure the stability of these pillars? Custom Fleet Management Software brings you the solution. Let us find out how.

Fleet Management and Technology

Before we dive into the many valid reasons why every successful company should have its own personalized fleet management software, let us first familiarize ourselves with what fleet management is.