AI-Powered

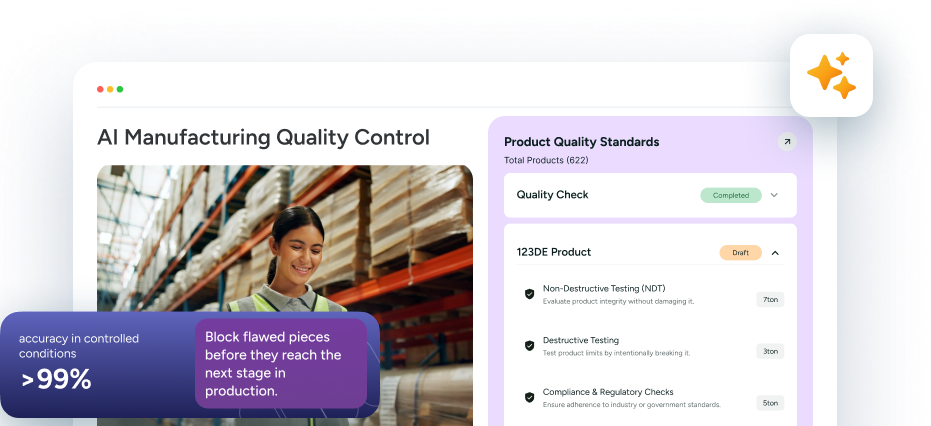

AI for Manufacturing Quality Control

Raising Product Standards With AI-Driven Machine Vision

AI-driven quality control shrinks production waste by up to 50%.

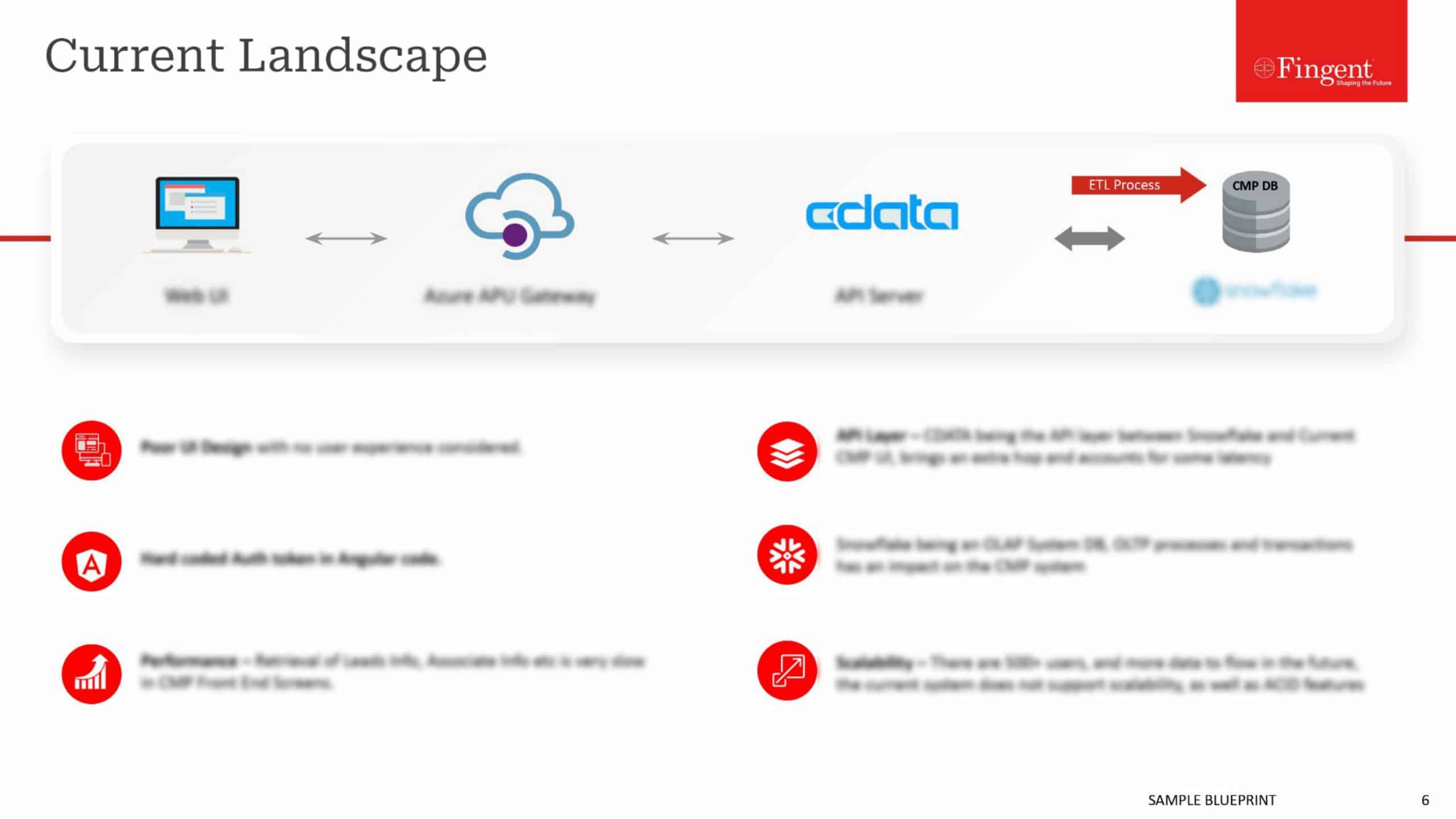

Challenges of Traditional Quality Control Methods

Human errors like external influence and distortion affect the integrity of manual inspections.

Minor flaws may go unnoticed, especially during monotonous quality assessments.

Growing output requirements surpass a manufacturer’s ability to perform manual audits.

Quality control performed on completed products can waste materials, time, and money.

Inefficient quality control comes with high costs– rework, scrap, product failures, and recalls.

Non-compliance with production standards can lower customer satisfaction and stakeholder confidence.

Looking for an intelligent solution to automate quality control?

The Solution:

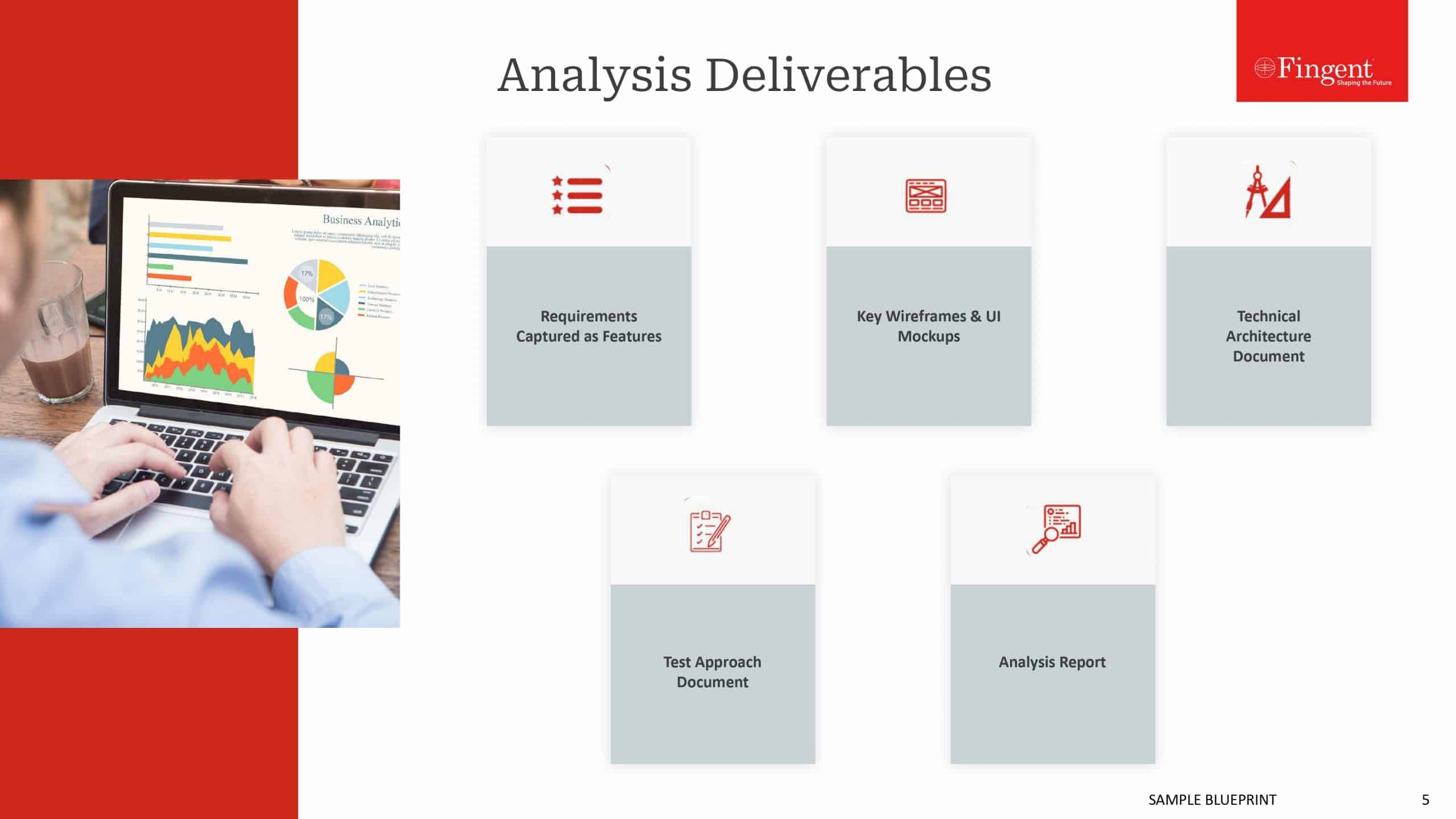

AI-Powered Vision Systems

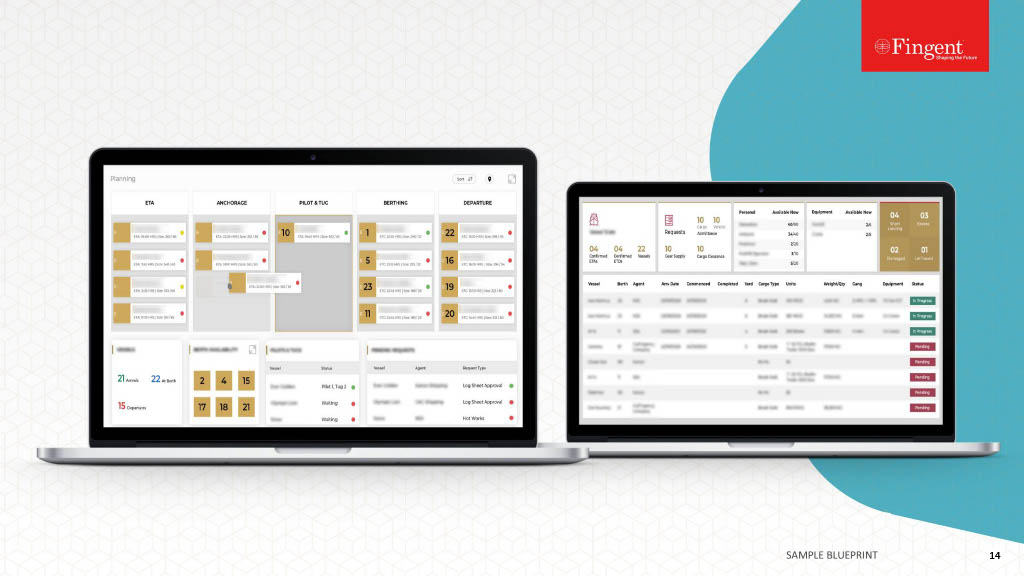

Alert line operators instantly to halt production or rectify errors.

Identify defects with >99% accuracy in controlled conditions.

Block flawed pieces before they reach the next stage in production.

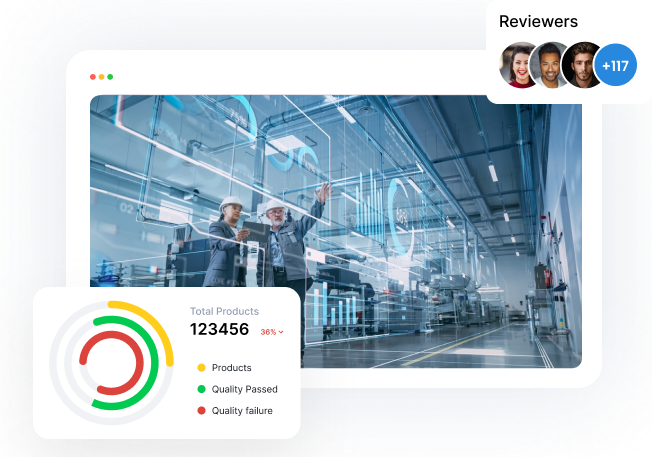

How Does AI-Driven Quality Control Help

AI Implementation in Quality Control Systems

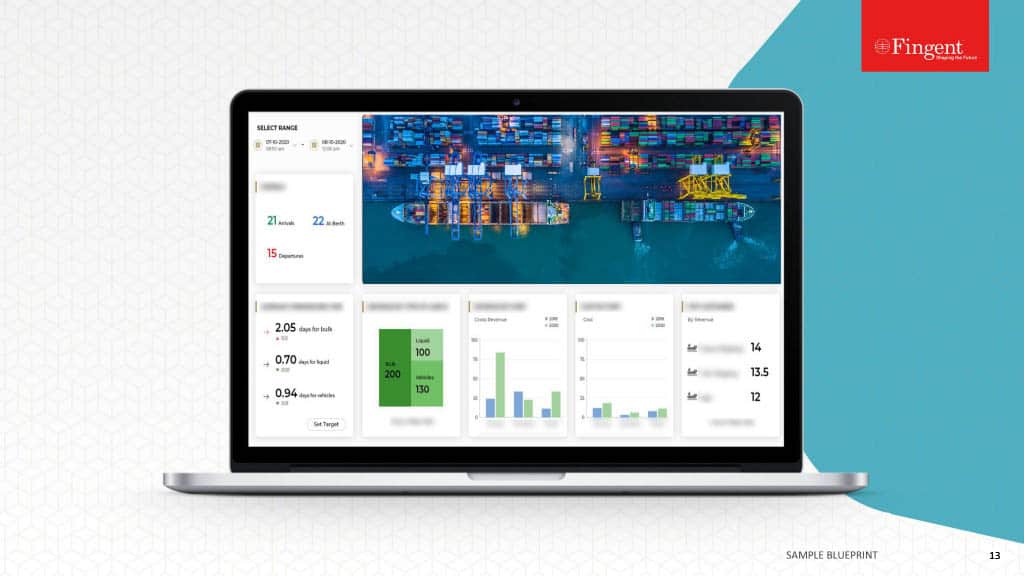

AI for Real-Time Quality Monitoring

incidents

reliability

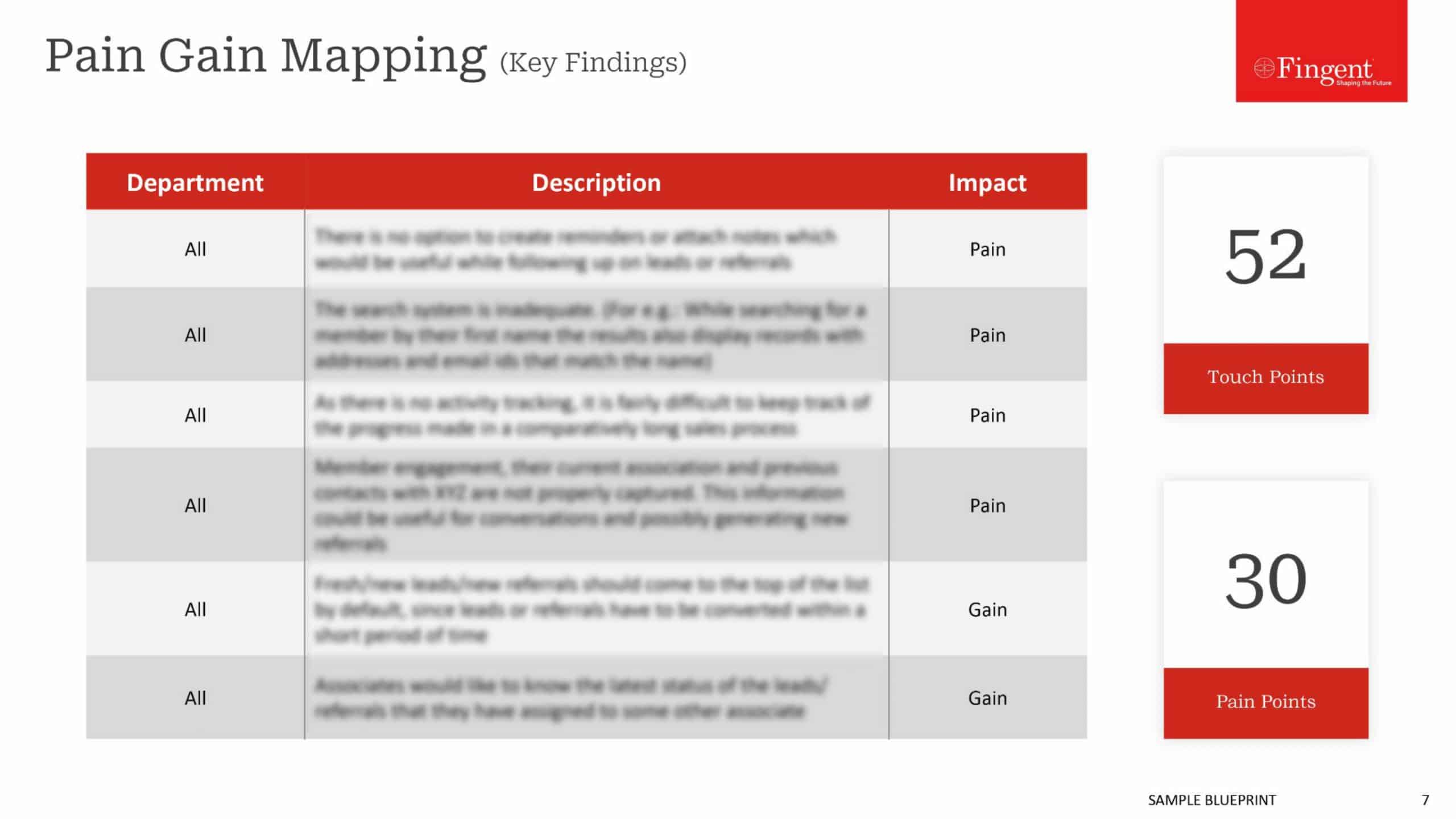

Benefits of AI-Powered Vision in Quality Control

Consistent, higher defect detection rates without any bias.

Save potential expenses incurred by material scrap and labor.

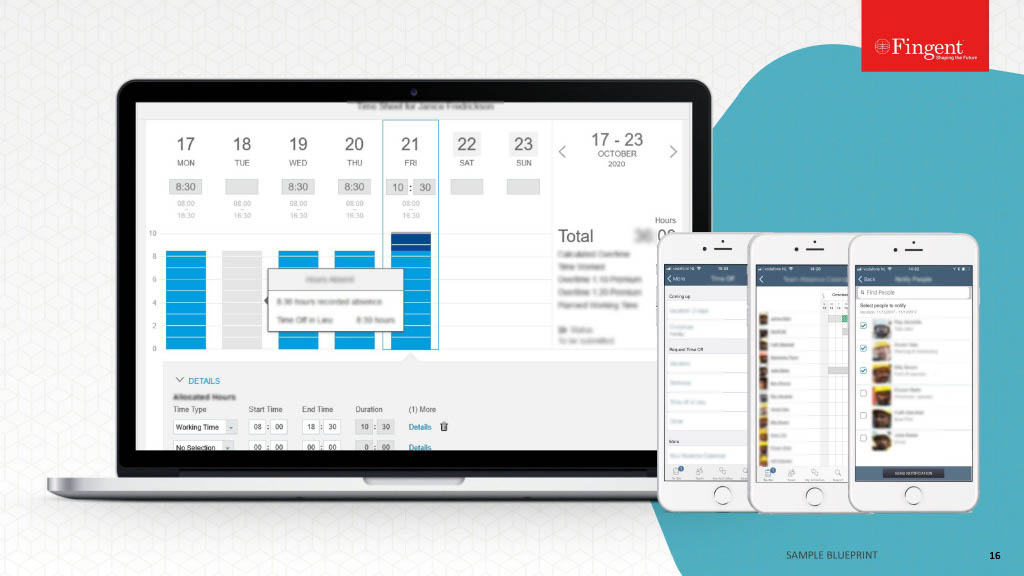

Overcome production snags with real-time monitoring.

Expand production volume without compromising quality.

Limit human involvement in hazardous inspections.

Better alignment with quality and safety standards in production.

Optimize your quality control workflow with AI.

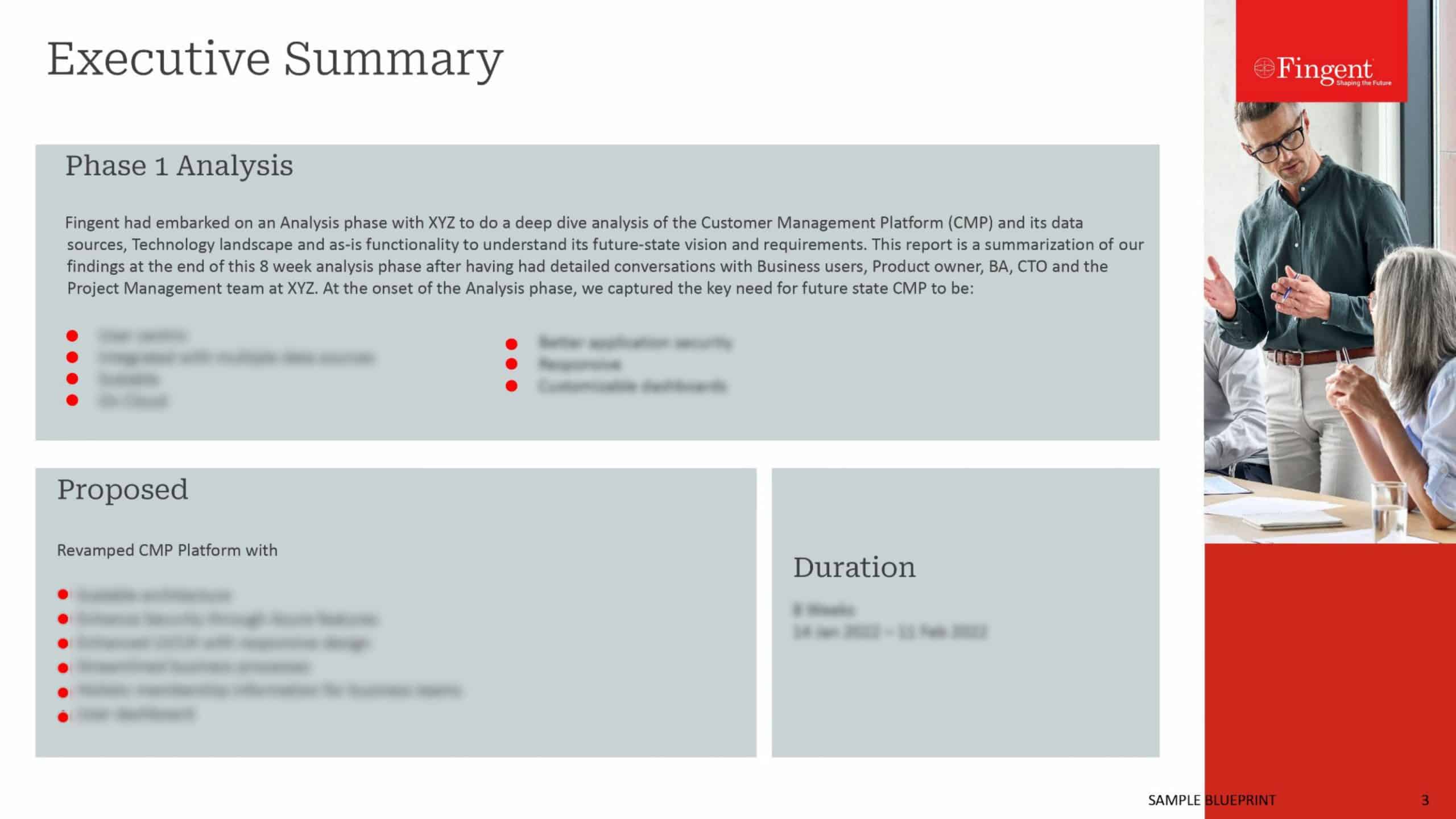

How Fingent Helps Manufacturers With AI-Powered Quality Control?

Design and deploy custom AI quality control inspection software

Tailored computer vision solutions to automate quality control workflows

AI Proof of Concept (PoC) and Minimum Viable Product (MVP) development

AI-led predictive maintenance applications for quality assurance

Real-time monitoring tools for quality inspection and incident alerts

AI-based production line optimization tools for manufacturers

Analytics solutions to evaluate production and quality-related insights

Key Takeaways

Enforce compliance with safety regulations that govern production and quality control practices.