AI-Powered Production Process Optimization

How AI helps unlock the full potential of your production process

Inefficient Production Lines: A production line becomes inefficient when it fails to produce the maximum possible quantity of goods with the resources available. Equipment maintenance issues, human errors caused by insufficient training, and other bottlenecks in the production flow can make production lines inefficient.

Inconsistent Product Quality: Producing goods that do not meet the vital product quality standards can lead to customer dissatisfaction, which can destroy your company’s reputation and customer goodwill. It will also increase your production waste, causing potential revenue loss.

Inaccurate Demand Predictions:Difficulty in predicting consumer demand can lead to shortfalls or surplus in production inventory, staffing, and equipment. Overprojection of demand results in excess stock, while underestimation causes production delays due to scarcity of material.

Incompetent Decisions and Process Delays: Manual processes used for gathering and analyzing data can delay information exchange, widen communication gaps, and even result in wrong decisions. It can even prevent workers from proactively identifying and solving problems.

Years of Partnership:

Extended Team Size:

Years of Partnership:

Extended Team Size:

Years of Partnership:

Extended Team Size:

Years of Partnership:

Extended Team Size:

Years of Partnership:

Extended Team Size:

Years of Partnership:

Extended Team Size:

Contact Us

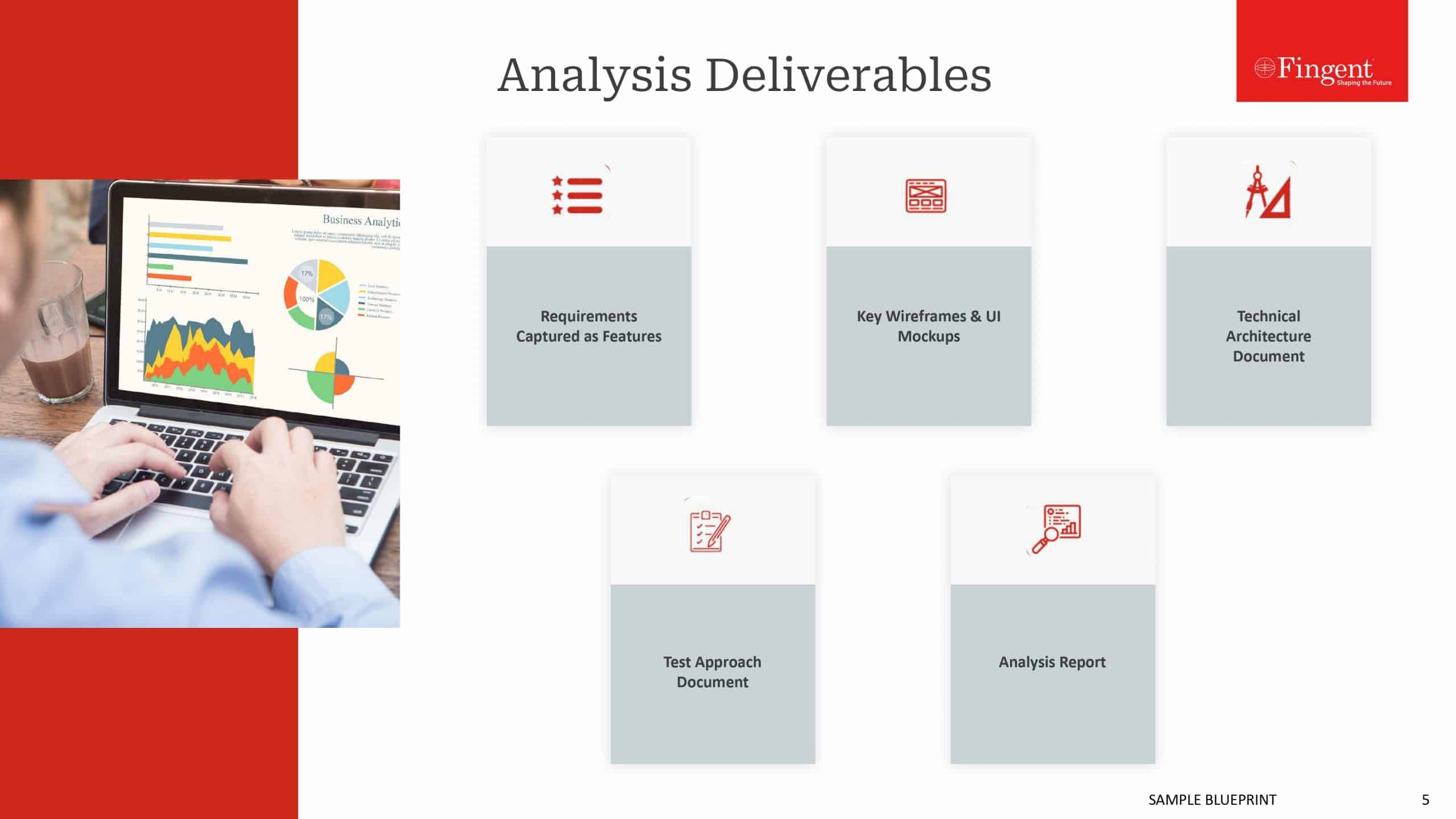

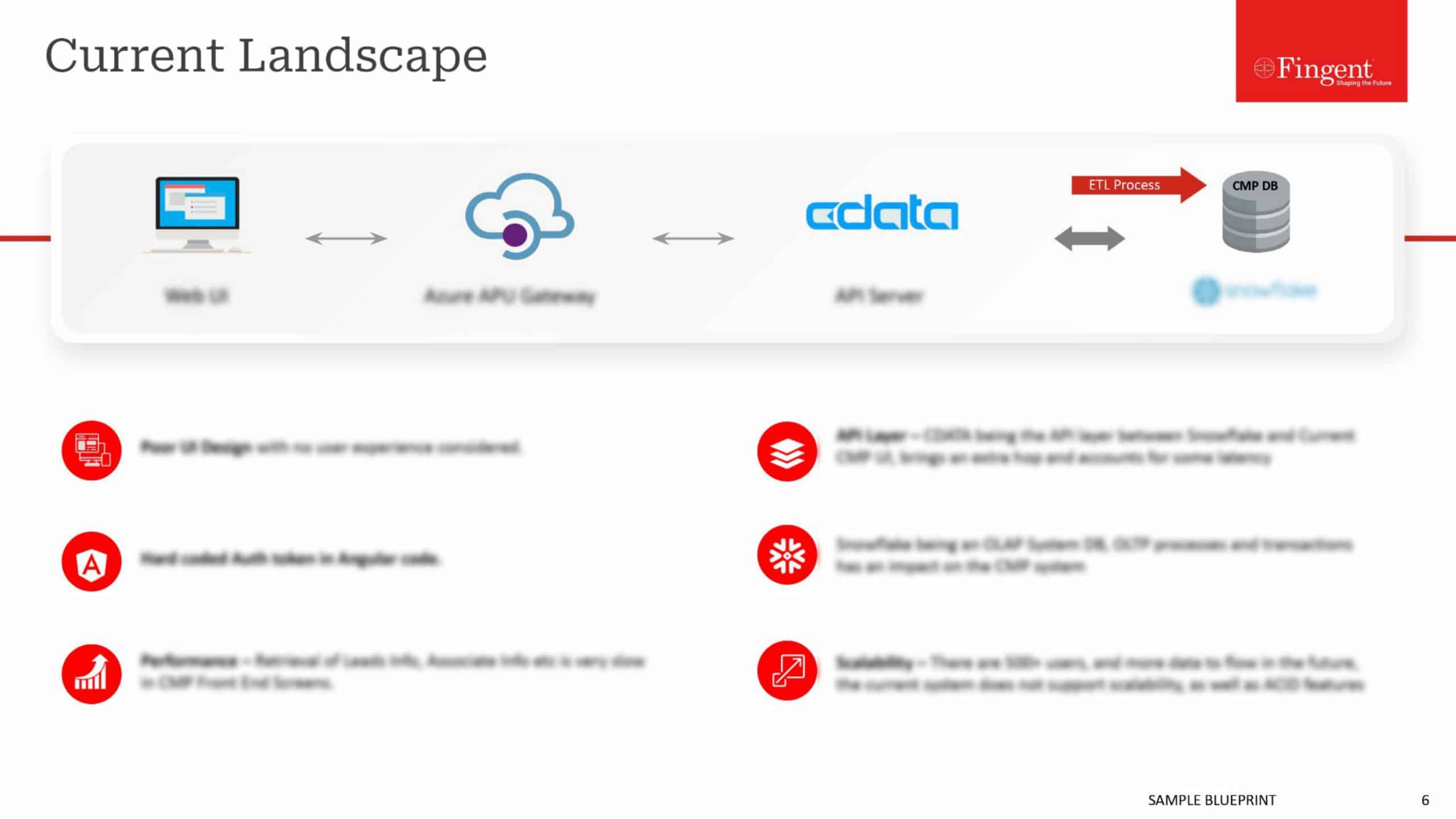

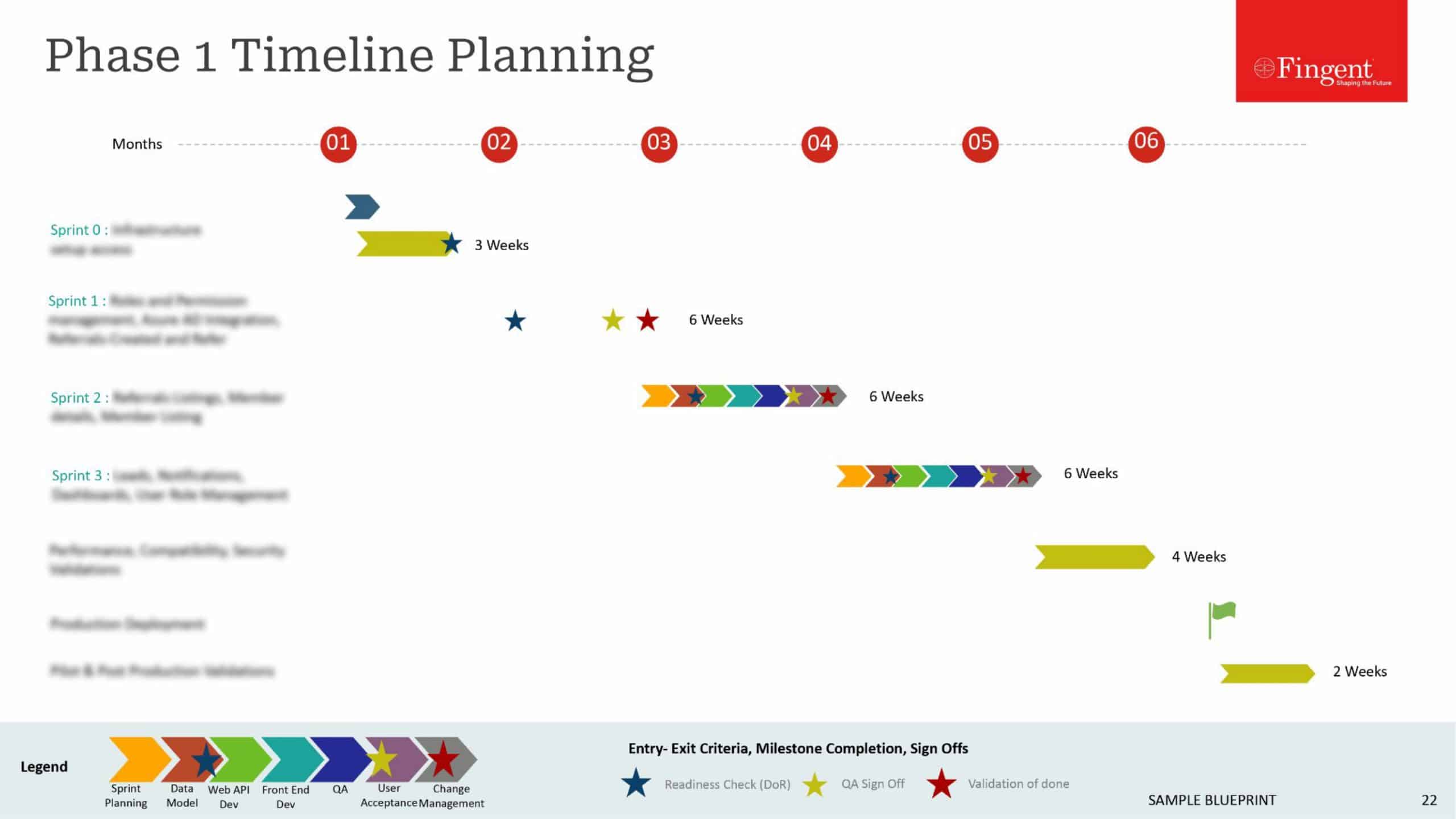

Sample Blueprint

Sample Blueprint