AI-Powered

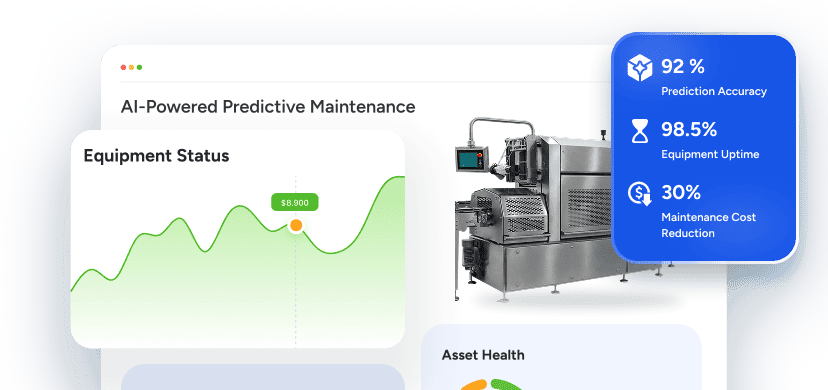

AI-Powered Predictive Maintenance

Increases Equipment Lifespan and Production Uptime

AI-powered predictive maintenance achieves 92% accuracy, outperforming traditional methods at 78%.

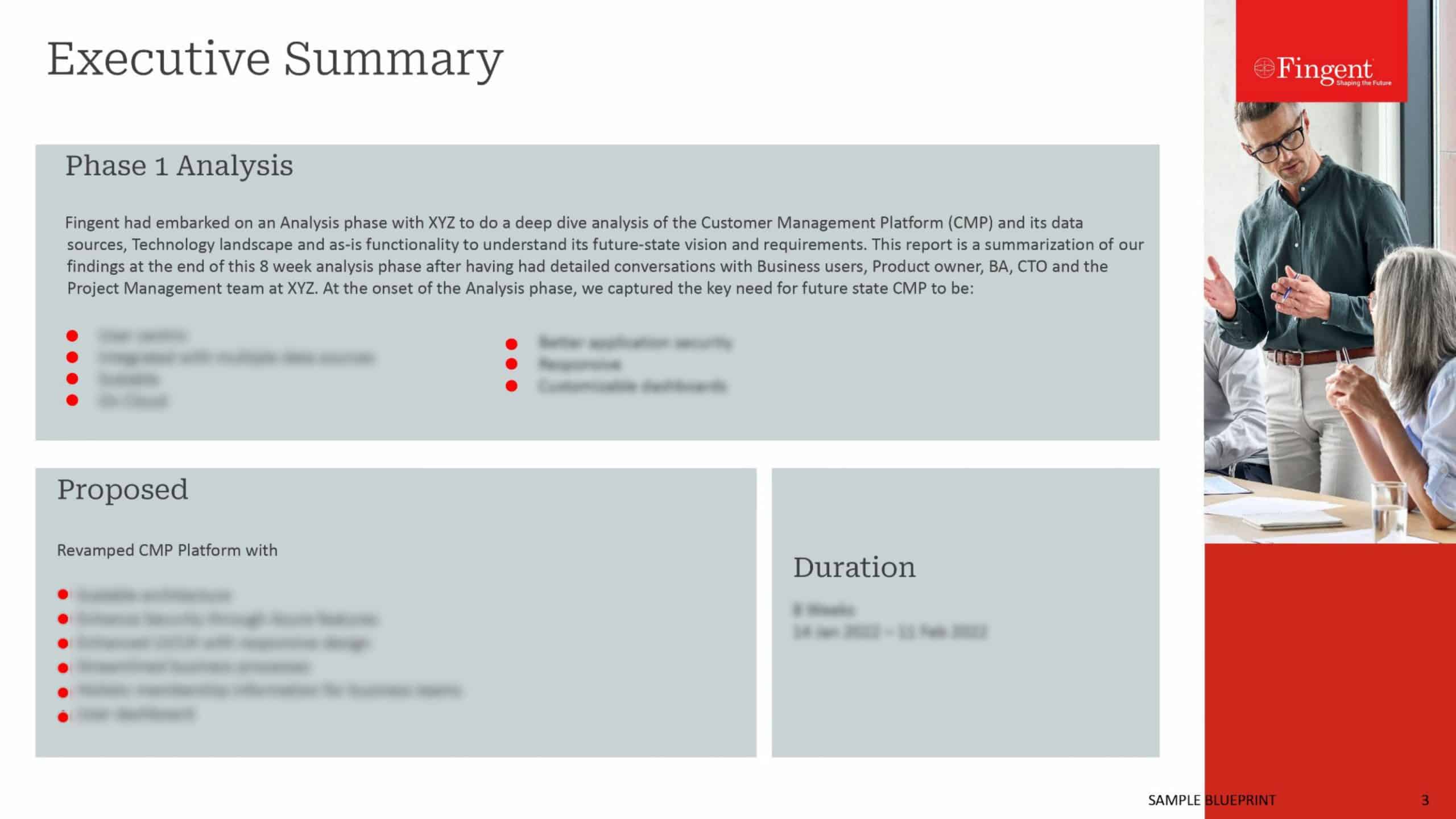

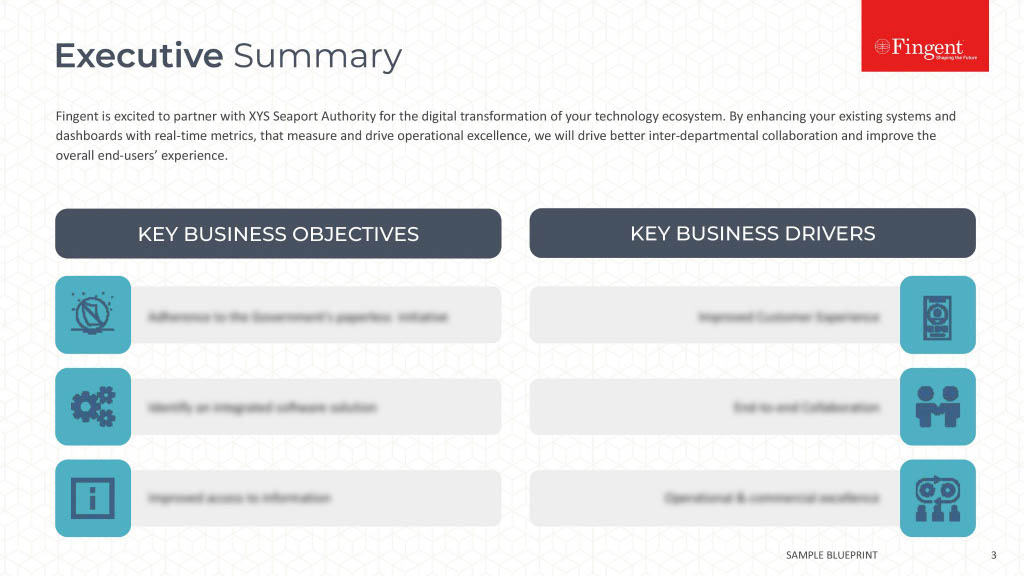

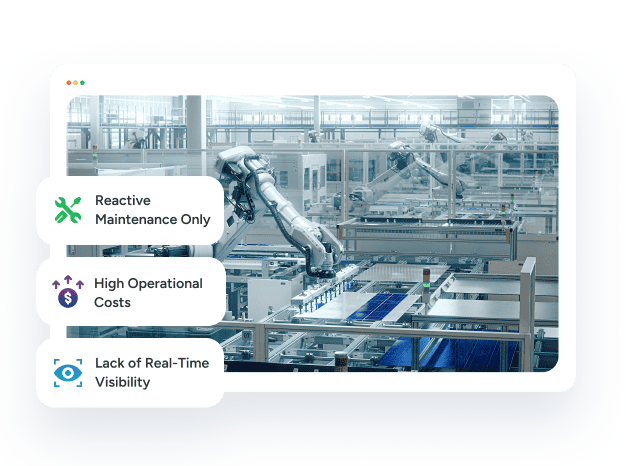

Challenges of Traditional Asset Maintenance Approach

Machinery failures are fixed only when issues occur

Maintenance is done solely based on predefined schedules

Under- and over-maintenance causing unwanted downtimes and costs

Underutilization of asset- and sensor-generated data

Maintenance personnel lose their quality time troubleshooting

Operational disruptions, costly production halts, and safety risks

Want to know how AI can enhance your equipment maintenance workflow?

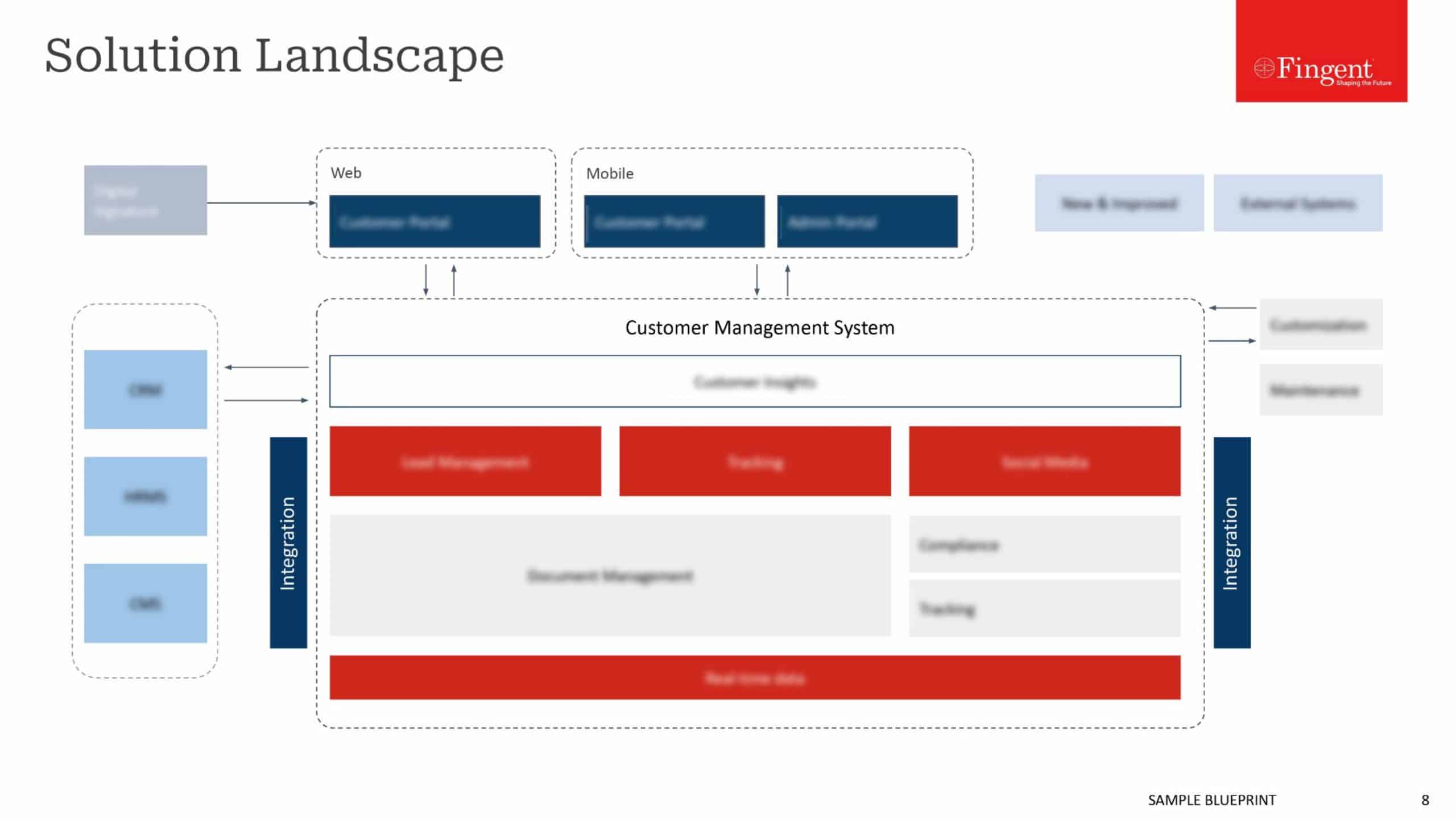

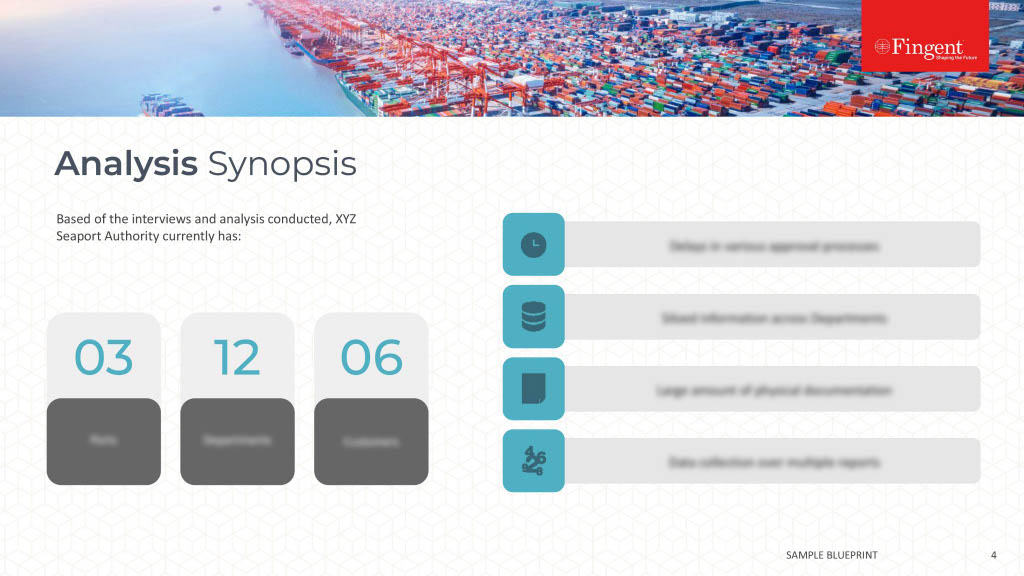

The Solution:

AI-Powered Predictive Maintenance

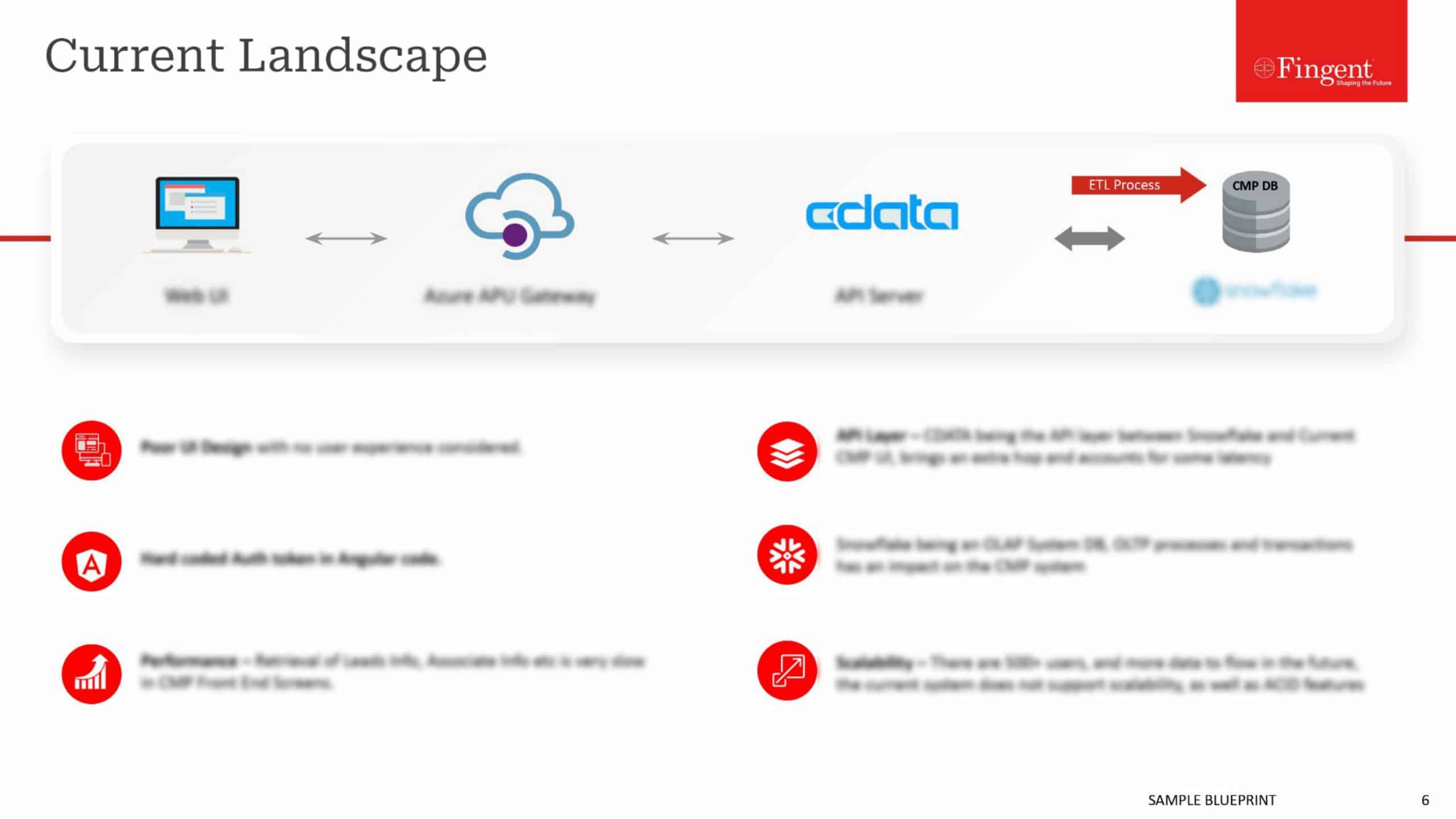

AI analyzes historical asset performance data and real-time sensor data to create a predictive model of equipment breakdown. It helps avoid outright equipment failure.

AI algorithms constantly monitor and analyze equipment condition in real-time to identify defects and anomalies. It helps in scheduling maintenance based on actual conditions, not a predefined schedule.

Predictive AI models can estimate when a piece of equipment is likely to fail based on current and past data patterns. AI can trigger alerts to maintenance personnel when any potential defect is identified.

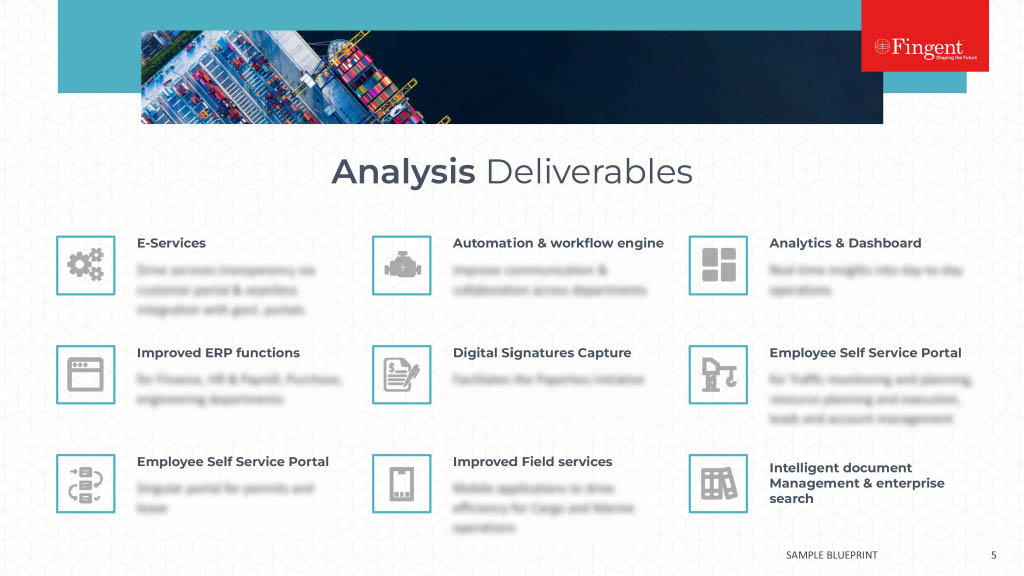

The Impact of AI-Driven Predictive Maintenance

Manufacturers Using AI in Predictive Maintenance Report:

Benefits of AI-Enabled Predictive Maintenance

Reduce machine outages with more accurate and faster predictions

Keep production lines rolling by boosting labor productivity

Improve occupational safety, health, and environmental compliance

Extend the lifespan, uptime, and performance of assets

Cut defect rates and production costs, improving quality and consistency

Reduce unwanted inspections, repairs, and costly replacements

Flag issues and recommend life-saving maintenance actions

Keep supply chains flowing, boosting productivity and revenue

Want to simplify your equipment maintenance with AI?

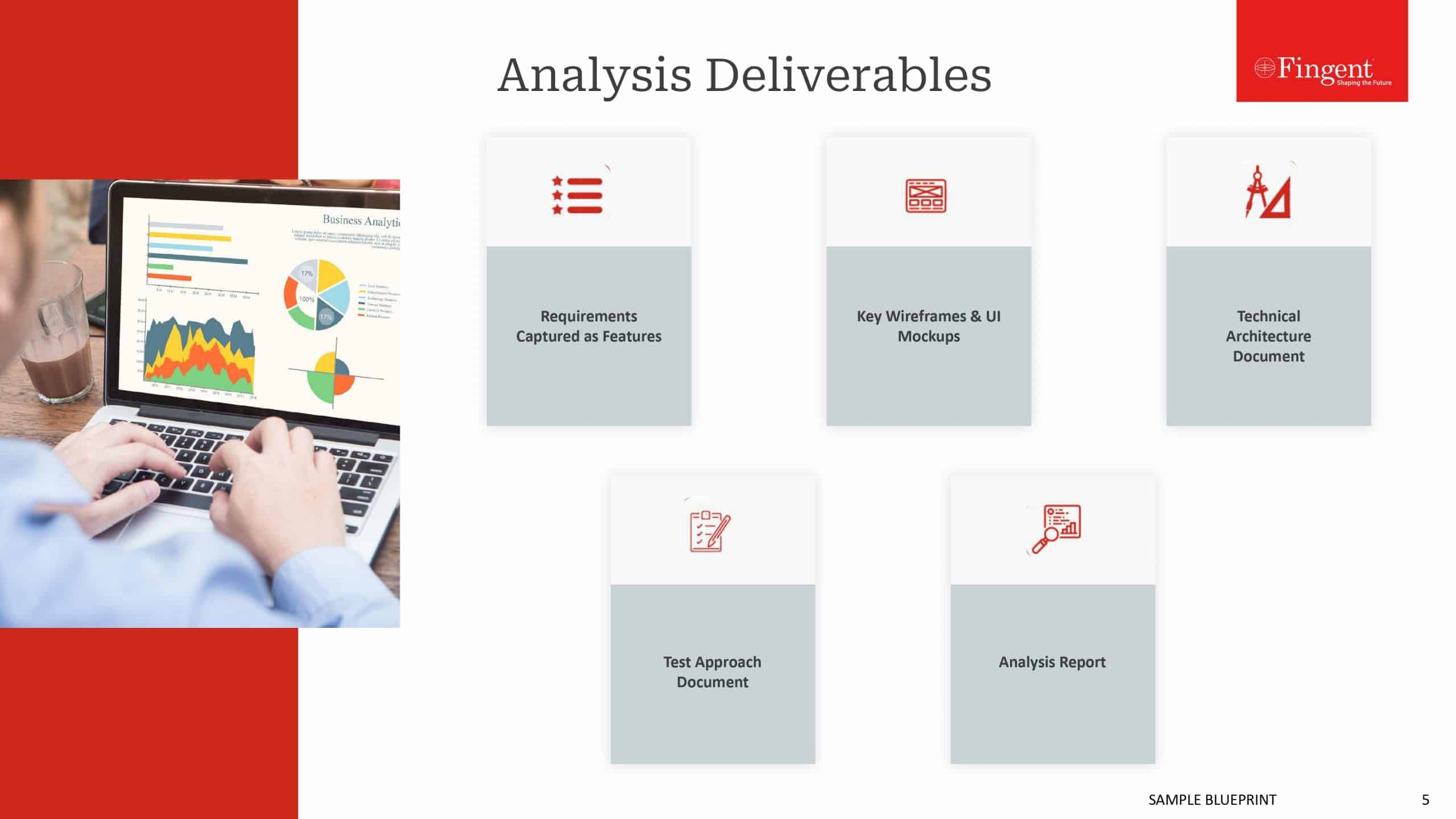

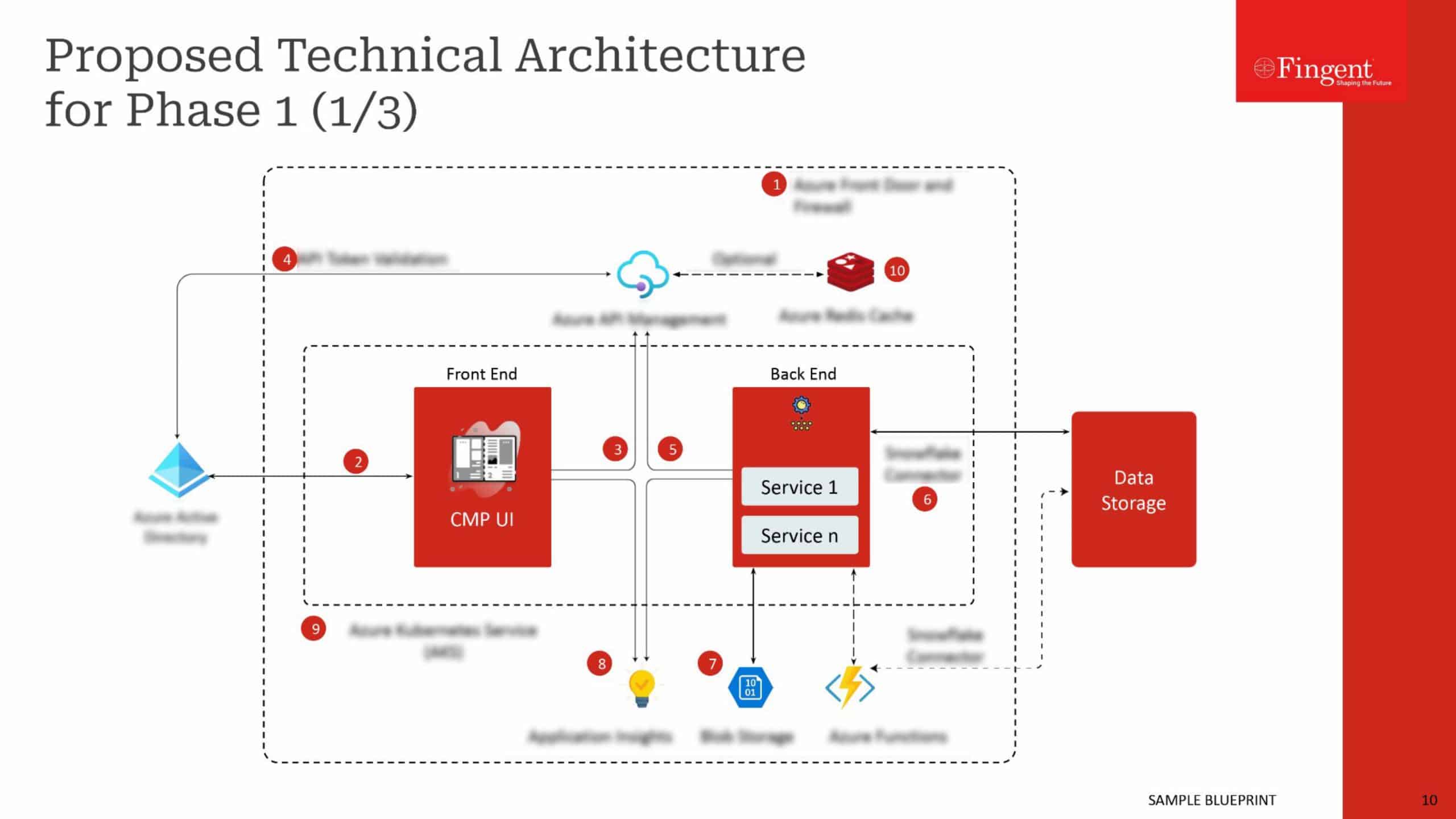

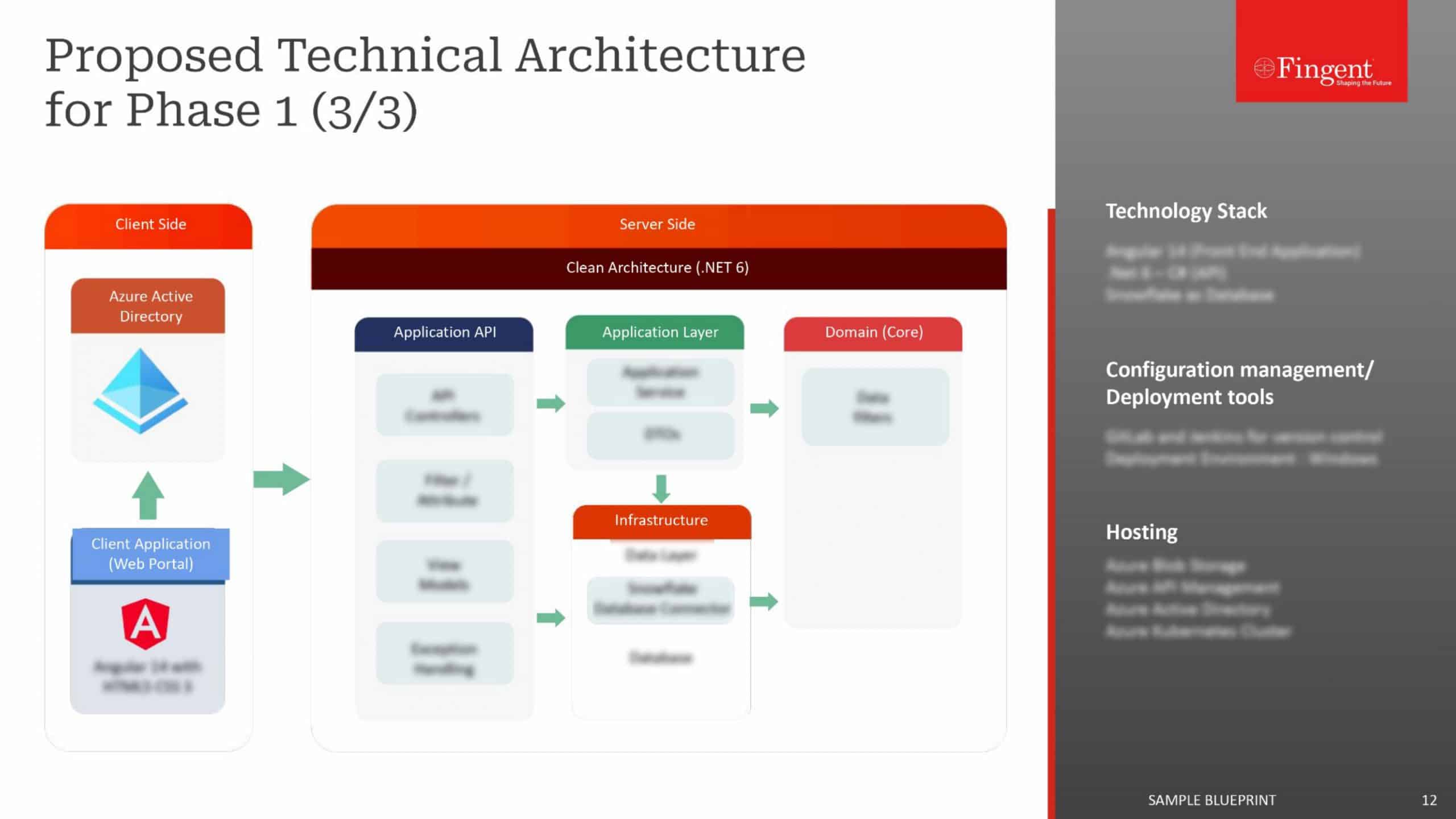

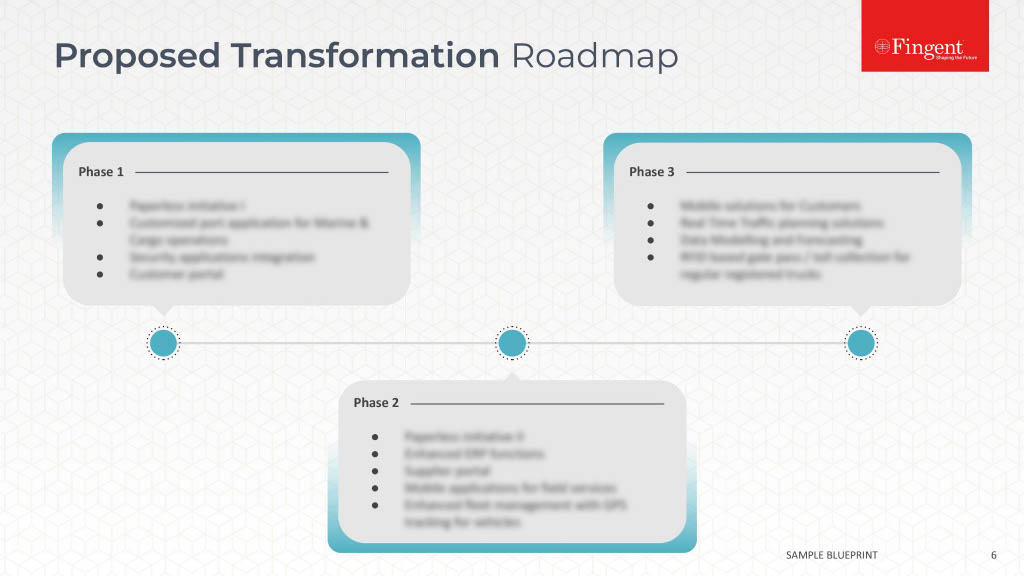

How Can Fingent Help With Your Predictive Maintenance Requirements?

AI and ML model development to predict asset performance and maintenance needs

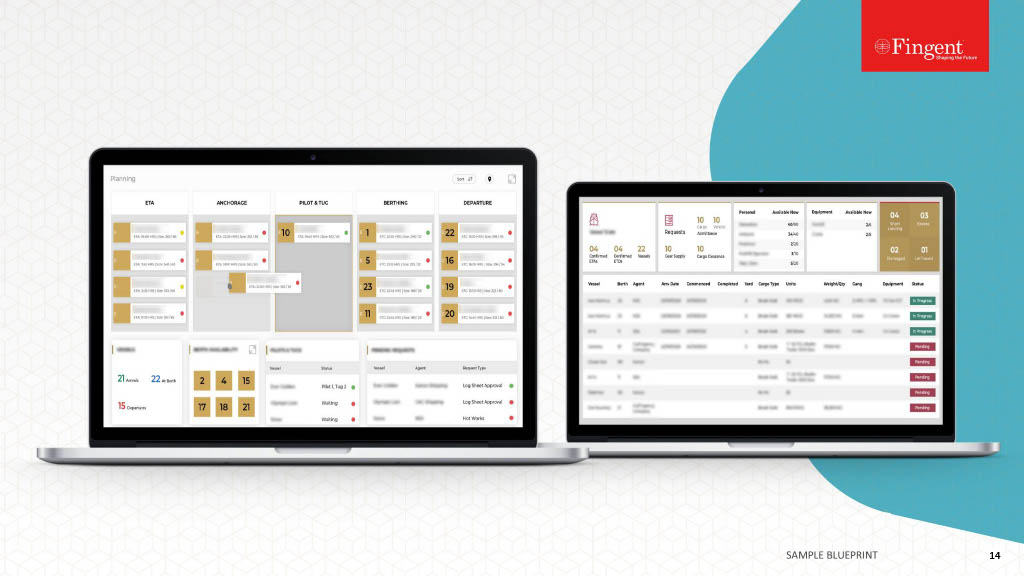

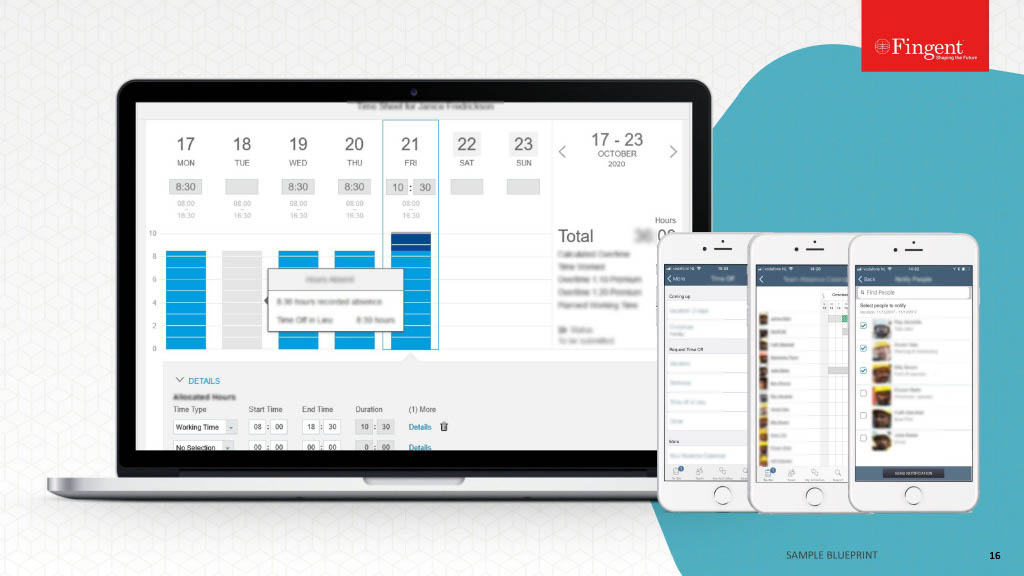

AI integration into your existing workflow to enable data-driven maintenance decisions and optimize asset performance

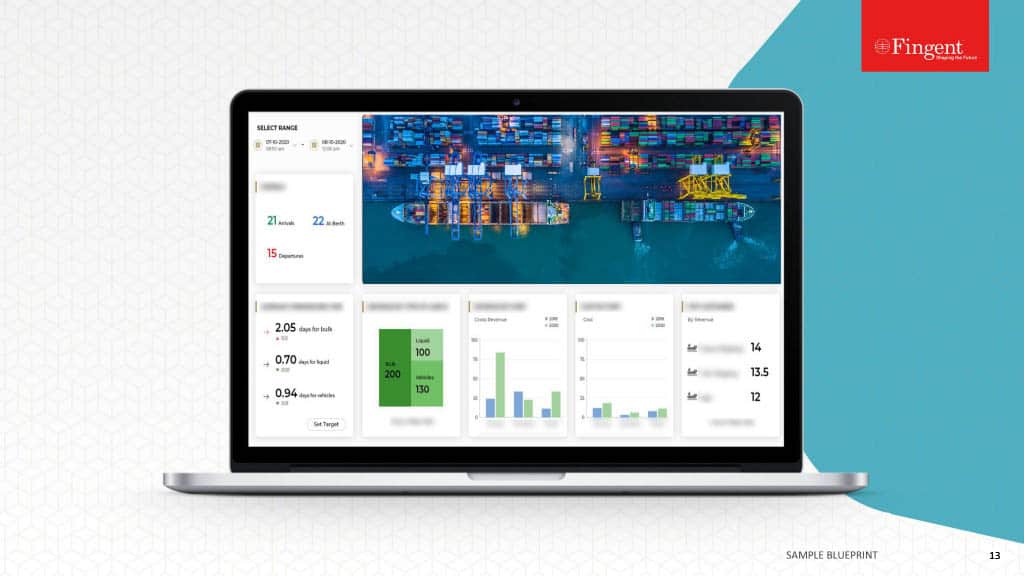

Data analytics and visualization services to offer businesses a single source of truth

Enterprise asset management solutions with advanced forecasting and condition-based maintenance

IoT and AI-powered remote equipment monitoring solutions to help asset managers

Key Takeaways