Tag: Logistics Management System

Can Cloud based Logistics Platforms help you? The logistics game is changing fast! The industry is under immense pressure to improve its efficiency and reduce costs. That is its one shot at enhancing customer satisfaction. For years, traditional logistics management systems have struggled. Outdated technology slowed their processes. But now, technology brings a game changer for businesses: Cloud based Logistics Platforms!

With these smart systems, your company can get real-time insights and boost scalability. It will help optimize your supply chain to get maximum efficiency. Are you prepared to safeguard your operations for the future? Let’s get started.

What Is the Primary Purpose of Using Cloud Based Collaboration Tools in Supply Chains?

Cloud-based collaboration tools aim to enhance teamwork in supply chains. They let people share information quickly and easily, no matter where they are. This helps teams work together better, make decisions faster, and stay organized. These tools improve efficiency and lower costs.

Supply chains thrive on precision. But when communication slows and data scatters, mistakes happen. Research from Gartner reveals that bad data costs companies an estimated 15% of their revenue, with the average financial impact reaching $9.7 million per year. Here is where cloud-based solutions come into play.

They eliminate silos and bring everyone involved onto the same page. Cloud-based services offer immediate access to data. Logistics companies can prevent interruptions, reduce errors, and make quick, smart choices. They improve supplier collaboration, resulting in reduced bottlenecks and greater overall efficiency.

Struggling With Outdated, Disparate & Disconnected Logistics Systems? It’s Time To Up Your Game with Cloud-based Logistics Platforms!

Top Benefits of Cloud-Based Solutions for Logistics Management

Statistics indicate that many are switching to the cloud. The global cloud logistics market is expected to reach US$ 46,313.9 million by 2030, growing at a rate of 13.6% per year from 2025. This growth shows businesses are recognizing the benefits of Cloud-Based Solutions for Logistics Management. Here are some of those benefits:

-

Real-time tracking and Visibility

The Challenge

Logistics teams often lack information regarding the whereabouts of shipments. This results in setbacks, misplaced packages, and dissatisfied customers.

The Solution

Cloud-based services offer comprehensive shipment tracking featuring real-time GPS information. This gives logistics managers clear insights. It helps them optimize package routes and cut down delays in delivery. It also addresses any kinds of disruptions that we expect on delivery routes. Customers benefit from accurate ETAs and automated notifications. These features help build trust in the brand and boost satisfaction with services.

-

Scalability on Demand

The Challenge

Customer requirements change throughout the year. When demand spikes, logistics systems find it hard to cope with the sudden pressure. They have to scale operations but doing so without incurring large upfront costs becomes difficult to achieve.

The Solution

Cloud-based solutions help businesses to scale their operations easily. You do not need expensive hardware upgrades to achieve that. Cloud platforms can tackle it all. They handle adding fleet vehicles, expanding warehouses, and managing seasonal surges. This lets businesses grow as they need, without the stress of a fixed infrastructure.

-

Cost Savings

The Challenge

Inefficient logistics often lead to high operational costs. This happens due to manual errors, poor route planning, and fuel waste.

The Solution

Say goodbye to unnecessary expenses with cloud-based solutions. These systems provide AI-driven route optimization. Workflows are automated and the system works on predictive analytics. These processes help cut fuel use, reduce human errors, and improve warehouse storage.

Businesses can shift from costly, physical IT setups to affordable cloud services. This change helps free up capital. This lets companies invest in other growth initiatives that will help them over time.

-

Better Teamwork

The Challenge

When warehouses, drivers, suppliers, and customers don’t communicate well, it can cause problems in logistics. This often causes delays in the process.

The Solution

Cloud based logistics platforms integrate communication tools like instant messaging, automated alerts, and shared dashboards. This ensures that all stakeholders remain informed at all times. Enhanced communication results in more effective teamwork, faster reactions, and reduced misunderstandings. This results in a supply chain that is more coordinated and effective.

-

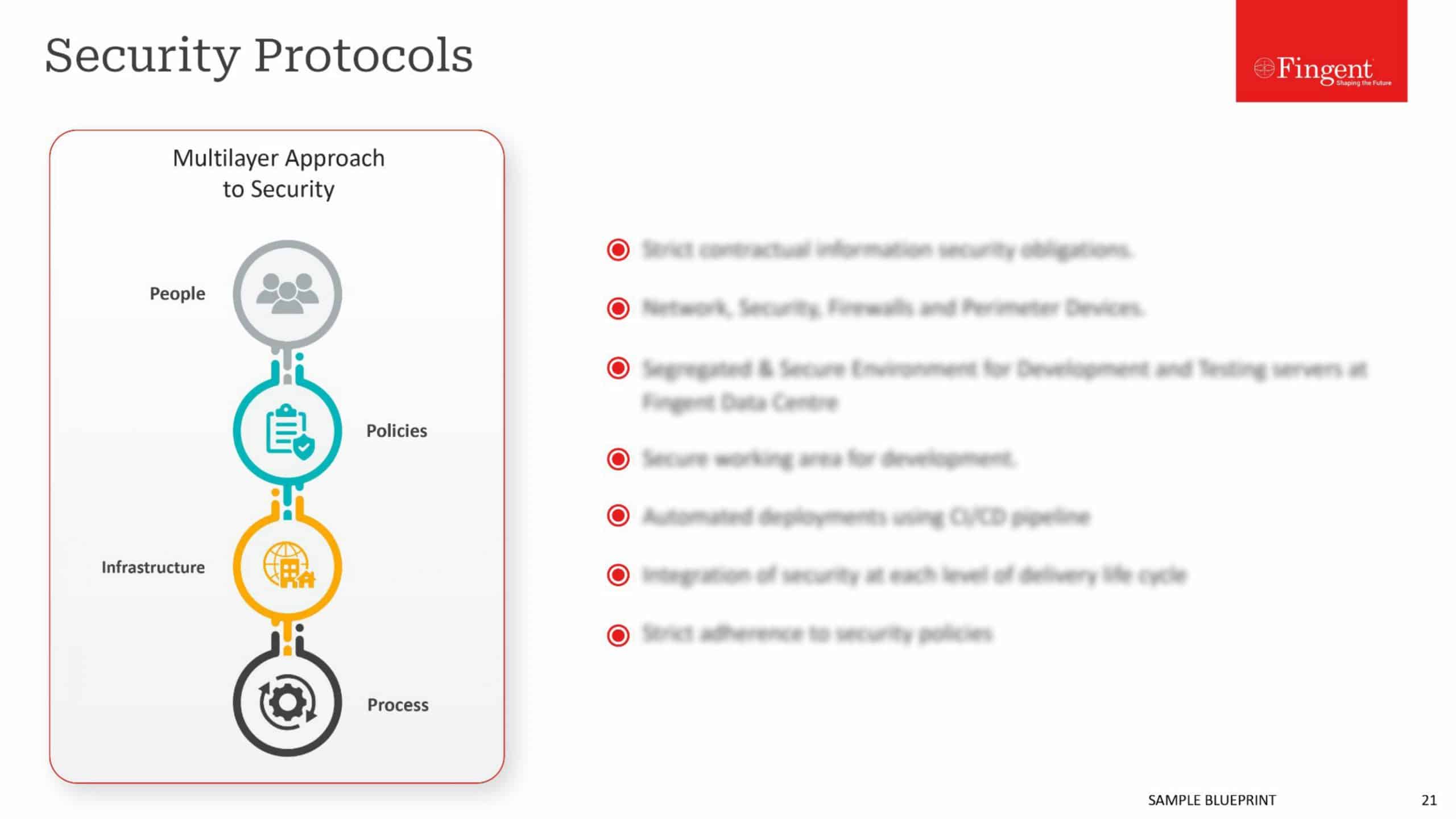

Security and Compliance

The Challenge

Companies deal with sensitive client information on a daily basis. Data breaches, fines, and not following industry rules don’t look good for security. This can put businesses at serious risk.

The Solution

Cloud-based platforms prioritize keeping data safe. They offer strong security features, like encrypted storage and multi-factor authentication. These protect against intruders. Their AI-driven threat detections safeguard sensitive data. Many of these platforms have built-in compliance tools. These tools help logistics companies follow important guidelines. This helps prevent costly violations.

Real-world Success Stories with Cloud Based Logistics

1. Turn Chaos into Control

The Challenge

Shipping companies lose a lot of time and money due to outdated logistics systems. Inefficient tracking systems and fleet management cause frequent delivery delays.

How Cloud-Based Tech Helps

By using a cloud based logistics platform, shipping companies can see their whole fleet in real time. This allows AI-powered route planning and an automated maintenance schedule.

The result? Delivery delays decrease significantly. Fuel use improves and becomes more efficient. Vehicles experience less wear and tear, which leads to substantial cost savings.

2. Warehouse Woes Fixed in E-commerce Giant

The Challenge

E-commerce players face frequent inventory mishaps. There are errors in fulfilment. Increasing order volumes become difficult to keep up with.

How Cloud-Based Tech Helps

A cloud-powered warehouse management system transforms operations by automating inventory tracking. The team can improve demand forecasting and streamline order fulfilment processes as a result. With real-time inventory insights, stock discrepancies drop. A large margin reduces customer delivery times. This helps grow clientele, strengthens brand loyalty and boosts repeat sales.

3. Cold Chain Logistics Enhanced

The Challenge

Global food distribution companies struggle with inconsistencies in temperature during transport. Due to this, many perishable goods are spoiled in transit. These goods cost a significant amount of money, and there are huge financial repercussions. Apart from that, many regulatory issues crop up.

How Cloud-Based Tech Helps

Integrating IoT-enabled cloud tracking helps monitor temperature and humidity in real-time. Automated alerts are sent to drivers and logistics managers. This helps them take quick action. This helps companies comply with food safety regulations and reduce waste.

4. Meeting Customer Demands Efficiently in the Retail Supply Chain

The Challenge

A national retail chain faced issues with delayed shipments and stock imbalances. This resulted in frequent out-of-stock scenarios and lost sales.

How Cloud-Based Tech Helps

A cloud-based supply chain management system enables real-time inventory tracking and automated restocking. An AI-driven forecasting system cuts down stockouts and boosts supply chain efficiency. Stores can keep shelves full, which keeps customers satisfied.

Discover Your Possibilities with Custom Logistics Software Development

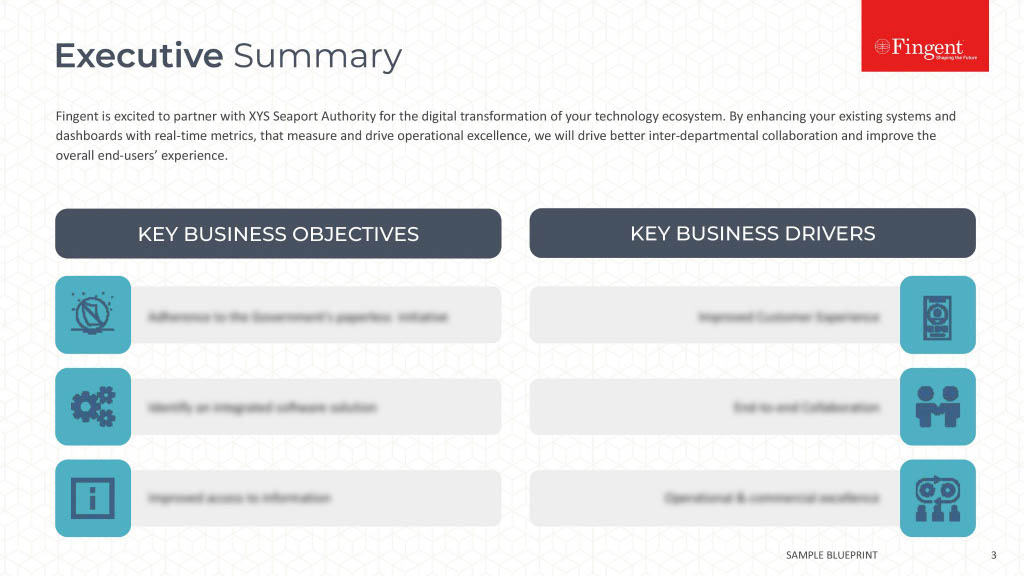

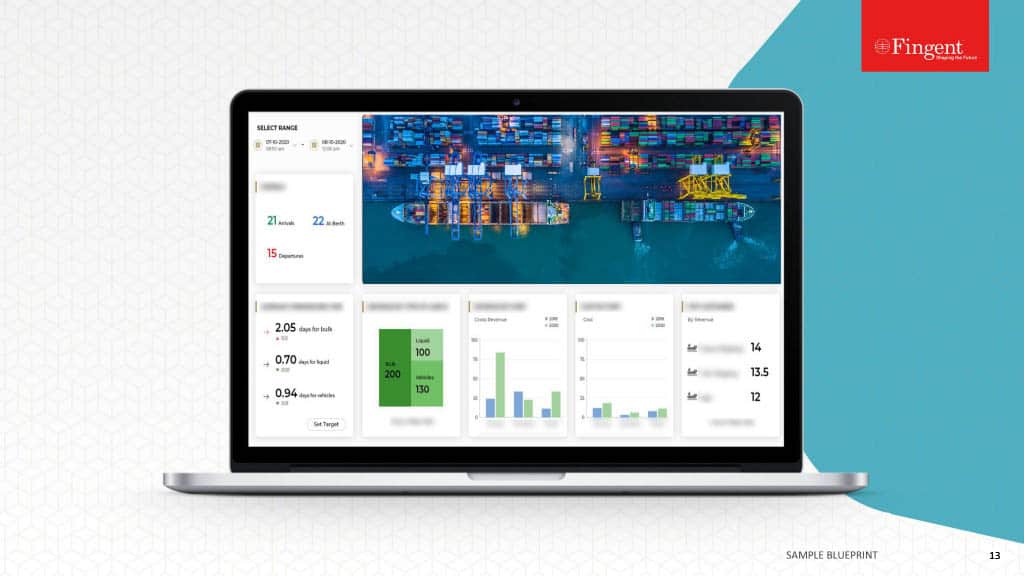

How Fingent Helps Logistics Companies Stay Ahead

In today’s fast-paced world, there is no time for errors. Cloud based logistics platforms are a must if you want to stay relevant. Be it real-time tracking or automation and cost savings, the cloud has got your back. It is the key to staying competitive.

Fingent empowers logistics companies to transform their supply chain. We leverage cloud technology, AI analytics, and automation for better results.

We have worked with clients globally helping them reduce internal workloads by 50%, increase their customer base by 43% within 6 months, gain a 60% increase in employee satisfaction and more.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

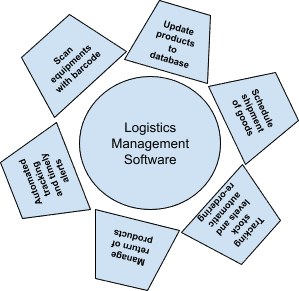

The onset of globalization has encouraged business operations on an international scale. It offers companies the opportunity to reach new customers in new markets. Exposure to unknown markets and sometimes even known markets can expose businesses to greater competition and greater risk. However, efficient management of the supply chain can do away with many of these risks and put you on the path to success.

The challenges in the supply chain can include being unsure of the reliability of your suppliers, and their quality, cost, lead time, lot size, and more. Your business will surely profit if you had a way to monitor your supplies and the risks to your business.

Yes, clear visibility is crucial.

This is where custom software can benefit your business!

Custom software equips you with a way to collect, organize, and monitor the supplier-related information that is most meaningful to your business. This blog discusses which functions of the supply chain can be better managed with custom software and also talks about the benefits this can bring to your business.

Why Is Customized Supply Chain Management Software Important?

Efficient management of the supply chain depends primarily on data gathered at each stage of the supply chain process. The success of the business hinges on the way companies use those insights to make decisions that optimize demand, supply, inventory, and deliveries.

That is why custom software is essential to managing the supply chain. Custom software can enable organizations to make better use of their data as it gives structure to the information already in their possession.

Through the use of custom software solutions, companies can identify faults in their supply chain process. Such visibility can help them make better inventory decisions or inform their customers of the shipping status for their confirmed orders.

Essentially, custom software is instrumental in improving business operations and relationships with both customers and suppliers.

Read more: Build or Buy Logistic Software: An End To The Prolonged Discussion

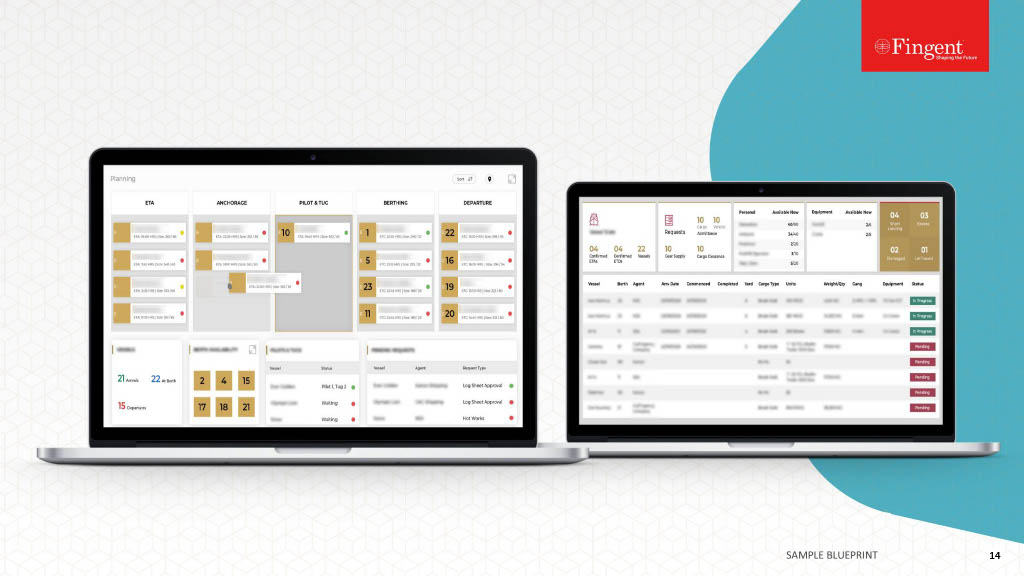

Manage Key Supply Chain Functions with Custom Software

Every business is unique in its functions. A software can address the specific company challenges only when customized and tailor-built after crucially analyzing the workflows and industry pain points. Here are a few to look into.

- Raw material acquisition: Supply chain management is a journey, and purchasing is at the beginning of that journey. Purchasing includes sourcing raw materials and other resources. Custom software enables smooth coordination with suppliers to deliver the material without any delays requires.

- Planning and forecasting: The operations team must anticipate the possible market demand and the number of units for production. Over-anticipated demand can result in excess inventory costs. If it is underestimated, then the company will not be able to meet its customer demand and thus lose revenue. Custom solutions for planning and forecasting can help the operations team to anticipate demands more accurately.

- Warehouse arrangement: Supply chain management requires warehouse arrangements till it is shipped for delivery. If the products are delivered outside the country or state limits, there will also be a need for outstation warehouses. Custom software can optimize logistics to reach end-point delivery without any glitches.

Advantages Of Custom Software in Supply Chain Management

1. Increased transparency throughout the supply chain

Knowing exactly where your item is at any given time is important for all businesses as it allows you to sell the item before it even reaches your warehouse. Custom software can help you sell this way because it can pinpoint the exact location of your item and the time that it will reach your warehouse.

This will allow you to provide a guarantee to your customer that he will receive the product he purchased. Streamlining the supply chain will help achieve faster response times and increase customer loyalty.

2. Efficient inventory management

With the help of custom software, you can sell your item while it is on the move or as it is in the making. It can help you estimate how many items you must produce, eliminating excessive production.

3. Supplier management

You can keep a good relationship with your suppliers with custom software. Real-time data will allow you to know if you are running out of stock or if your tools and equipment need repair or replacement. This data will help you contact your suppliers immediately and thus minimize any potential delays.

You will also have details such as account receivables and other information at your fingertips when dealing with your suppliers. This will ensure that you are up to date with payments and discounts. As a result, you notice that your communication and cooperation with dealers and vendors improve considerably.

4. Streamline Processes

Custom software will create highly streamlined processes for supply chain management, especially for businesses that operate from different locations across the globe.

Fully customized software enables companies to accumulate all business data in one centralized location. Employees greatly benefit from this as they can now gain access to the latest versions of data, even if they are accessing it from multiple locations or branches.

5. Un-bottleneck your supply chain

Bottlenecks in the supply chain are a direct result of the ineffective system in place that does not allow teams in different locations to communicate and align statuses to fulfill overall objectives. Companies that experience such bottlenecks miss opportunities and lose customers because they are unable to provide what their customers want.

An unsatisfied customer walks out on you and straight into the open arms of your competition. If you are beginning to notice lower satisfaction rates, numerous complaints, or bad reviews from the customers, it is time to explore custom software that can give you a business-targeted approach to customer experience.

When a business looks to meet or exceed customer demands, they have to rely heavily on its supply chain. Internal bottlenecks can slow down the entire process and risk order fulfillment. To prevent such bottlenecks, a business must understand what causes them and how to prevent them.

Custom software can help a business identify such bottlenecks and thus help efficiently manage the supply chain.

Save Money, Time, and Your Business!

It is clear that custom software comes with many benefits. It is also obvious that it saves money with time. While off-the-shelf software may come with a lower initial cost, investing in custom software will give more benefits to the supply chain management cycle. It improves sales functions and boosts productivity.

Custom software that is fully optimized to the supply chain will improve business function in a way no off-the-shelf software can. Fully optimizing the supply chain process can be lean and seamless through the use of custom software. If the business growth process is left unchecked by the off-the-shelf software solutions it can become highly chaotic. Custom software gives companies a higher level of control over all supply chain operations while taking control over the growth process.

A company that is digitally driven by custom software automatically enables a more proactive and open business. If this is what you want for your business, give us a call.

Our experts at Fingent thrive on creating custom solutions for our clients. They will be happy to talk through the game plan with you and show you how your business can excel with custom software for your supply chain.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

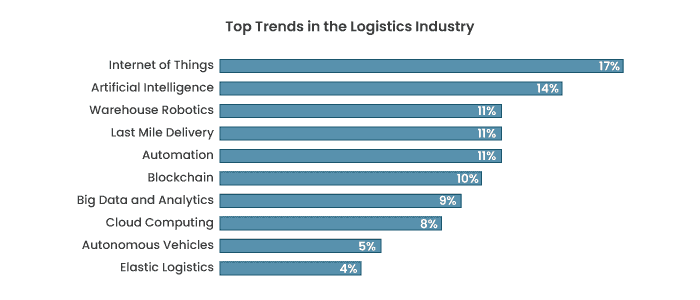

The logistics sector has become a key performance indicator of the economy. Various estimates put the total market size of the logistics sector in a country on an average to be between USD 90-125 billion!

The Current Sketch of the Logistics Market Place

Logistics and transportation managers often find the movement of freight between trade partners an uphill battle! It is necessary to make the transit easier, cheaper, and more efficient. The freight managers turn to Transportation Management Systems (TMS) for a smooth operation. Over the last 3 decades, such systems have evolved significantly and are typically available as standalone software packages, as part of a larger Enterprise Resource Planning (ERP) solution, or in Software-as-a-Service (SaaS) formats.

Logistics cost is 9% of the GDP in the U.S. This shows an increasing demand on the logistics sector to provide solutions, which are required to support future growth.

Looking at TMS as “one of the fastest growing enterprise application markets” in its most recent TMS Global Market Research Study, ARC Advisory group says that a gigantic 63 percent of companies would witness at least a 5 percent increase ( that is, 23% stated a 10 percent or more increase) in total freight costs if they had to forsake their TMS and get back to more manual transportation planning and execution processes. According to ARC, a Logistics achieves large savings based on process enforcement, visibility, analytics, and optimization, “with virtually no other supply chain application offering so many different forms of optimization.”

Related Reading: Top Challenges Faced by Logistics Management Today

Top Areas to Focus on a Long Term Logistics Strategy

According to survey reports in the “Transportation Management Systems” Study by the Peerless Research group and Logistics Management, and some other Successful Logistics Businesses, the top areas that are important when looking forward to a long term logistics strategy are:

- Maintaining high levels of customer service (96%)

- Lowering costs (94%)

- Improving efficiencies and productivity in logistics operations (93%)

- Achieving the ability to target logistics initiatives that drive business growth (79%) Improving Asset Utilization (74%).

Other factors involved are as follows:

- understanding and controlling costs (55 percent),

- better shipment planning (55 percent), and

- greater in-transit visibility (52 percent).

- electronic communications with customers and carriers (45 percent),

- overall supply chain processes (45 percent), and

- carrier and partner collaboration (43 percent).

These key factors are important to carve out a long term solution for their business growth and to remain sustainable and cost-effective in their transportation expenses.

Maintaining High Levels of Customer Service Is Essential In Logistics Services

Logistics partner is the company that ensures the delivery of your products on time and cost-effectively. A single rupture can be fatal to your company. Hence it is important to monitor the quality of the product or direct service provided. Since for many online businesses, the final touchpoint with their customer is their logistics provider, customer service is the most essential factor in Logistics!

With the benefit of logging in whenever and wherever required to know the shipping details, a TMS allows analysis of various reports to know the delivery details of carriers. Based on this data, greater predictability can be ensured along with providing a hassle-free delivery of the product to your customer.

The same data can also be used to interact with carriers and other members in the supply chain. This helps in resolving issues if any and proactive improvement which leads to an increase in the customer service metrics.

Lowering Costs with A Properly Managed Logistics System

Poor logistics analysis, planning and decision making can result in excessive expenditures, missed delivery deadlines and damaged goods. This is why optimizing operational efficiency and reducing logistics costs are essential factors to remain financially viable. Here are a few factors that affect Logistics costs:

- Increase In Fuel costs.

- Delayed arrivals at ports, that leads to higher transportation fees.

- Complex regulations that govern international trade such as document processing, compliance checks, and so on.

- Frequent delivery delays and increased warehousing expenses.

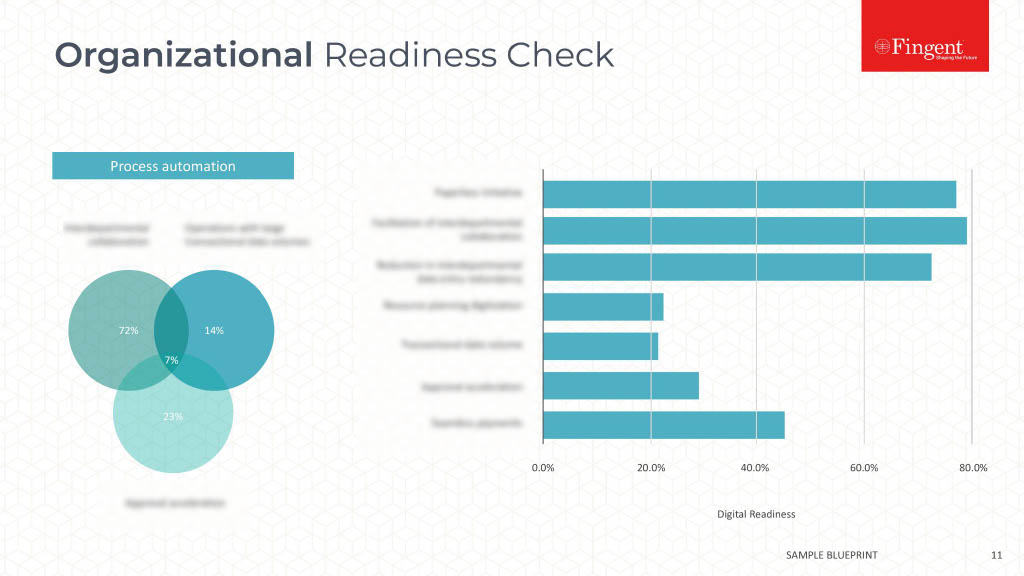

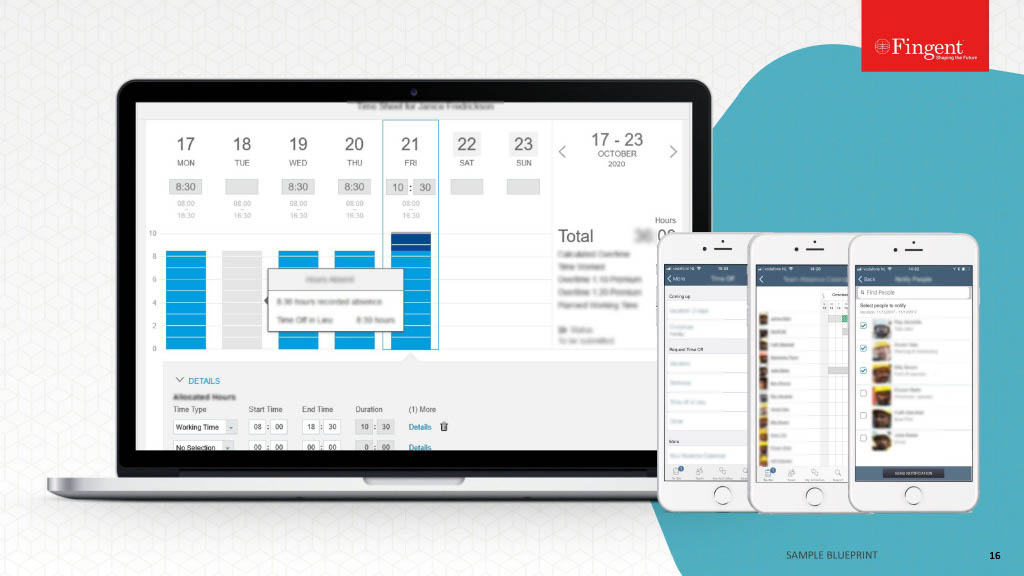

Process Automation

The logistics business drives on quick service and fast turn-around times. Yet, there is a lot that goes on in the background before a shipment or a truck is in transit. The reality is that a lot of these processes are manual and eat up a lot of time, which adds to the overall TAT. It is evident that ongoing investments are made in automating processes and this gives one the choice to expand without increasing other additional overheads.

As mentioned earlier the logistics industry is witnessing a continuous growth. Although there are multiple challenges that exist in this industry, the growth of logistics is going to be a very key indicator of the performance of our economy.

Improving Productivity in Logistics Operations with a TMS

The first step to achieve a Logistics task is planning. With proper planning, we will be able to prepare for the unforeseen circumstances. These situations can be related to:

- The products

- Unavailability of the transportation

- Any internal issue in the organization

- Research and pick the correct goods.

This is where Automation has a vital role in business process optimization. When automation is deployed in the logistics process, timely updates regarding the movement of goods will be provided. The service operator and the customer will get details regarding:

- The goods that are dispatched from the supplier

- Procurement of the products at the warehouse

- Delivery of the goods at the destination

This saves a considerable amount of time because manual interference is eliminated. Moreover, accurate tracking helps in improving the overall process management. Similarly, the account details and employee details can also be managed.

Targeting Logistics strategies that Drive Business Growth

Trumping over your competitors is possible with proper logistics strategies. This is because logistics costs are related to improved efficiencies. With proper strategies, every logistics firm that is struggling to boost their operations can incorporate these strategies for a proper logistics network optimization.

Improving Asset Utilization and Warehouse Management with a TMS

Common warehouse logistics challenges revolve around every Logistics industry The concerns can extend into extending into inventory management, cost controls, human resources, risk management, and security, among other factors.

With a proper logistics system that is integrated with your ERP or Warehouse Management System, you can easily start to calculate asset utilization! For expedient logistic solutions and seamless technological transformation, reach out to Fingent, the top custom software development company and Unlock the power of prompt logistics solutions while embracing their expertise in cutting-edge technology.

Related Reading: 5 Emerging Trends That Logistics Managers Cannot Afford to Ignore

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new