Tag: Supply Chain Management

Supply chain management is a complex web of processes that involve the seamless coordination of procurement, production, distribution, and more. Among these, inventory management stands out as a pivotal aspect that can make or break the entire system.

Maintaining control over inventory is like keeping a careful eye on the pieces of a chessboard. Every move counts, and any miscalculation can have far-reaching consequences. Imagine trying to play chess without knowing the current position of your pieces or your opponent’s – chaos would ensue.

In this blog, we delve into the common challenges faced in supply chain management concerning inventory control and explore the merits of building a custom inventory tracking system to address these issues.

Diving into the Nuts and Bolts: Common Inventory Management Challenges

1. Running Out and Piling Up: The absence of real-time tracking often leads to discrepancies between recorded and actual stock levels. This discrepancy can result in stockouts or overstock situations. Have you ever reached for your favorite snack only to find an empty bag? That’s what a stockout feels like for businesses – missed sales and disappointed customers. On the flip side, having too much inventory is like buying more snacks than you can eat – it leads to unnecessary costs and storage challenges.

2. Data Silos: Traditional inventory systems are often isolated, creating data silos that hinder communication and collaboration across different departments. This lack of cohesion can lead to inefficiencies and errors.

3. Forecasting Difficulties: Accurate demand forecasting is challenging without real-time insights. Businesses often struggle to predict market trends and consumer demands, leading to suboptimal inventory levels and increased holding costs.

4. Manual Processes: Relying on manual processes for inventory management is not only time-consuming but also prone to errors. It is like trying to juggle a dozen eggs without a basket. This can result in discrepancies between recorded and actual inventory levels, leading to operational inefficiencies.

5. Lack of Scalability: Many off-the-shelf inventory management solutions may lack the flexibility needed to adapt to the unique demands of a growing business. This lack of scalability can hinder long-term success.

How Can an Inventory Tracking System Help?

A custom inventory tracking system serves as a key strategic tool, providing businesses with a competitive edge in managing inventory complexities. Let’s now explore the concrete benefits of implementing such a system and its targeted solutions to common supply chain challenges.

1. Real-time Visibility:

An effective inventory tracking system grants you real-time visibility into your stock levels. This transparency enables timely decision-making, reducing the risk of stockouts or overstock situations. By knowing exactly what is in your inventory at any given moment, you can optimize stocking levels and respond swiftly to changes in demand.

Read more: AI in Supply Chain and Logistics

2. Cost Savings:

A well-designed tracking system allows you to minimize carrying costs by preventing excess inventory buildup. By optimizing stock levels and improving order accuracy, you can reduce holding costs, warehouse space requirements, and the costs associated with expedited shipping due to stockouts.

3. Enhanced Accuracy:

Manual tracking methods are prone to errors, leading to discrepancies in stock levels and financial records. An automated inventory tracking system eliminates human errors, ensuring accuracy in your records. This not only improves financial reporting but also builds trust with your customers and stakeholders.

4. Efficient Order Fulfillment:

An inventory tracking system streamlines the order fulfillment process by providing insights into available stock, order status, and delivery timelines. This efficiency contributes to a positive customer experience and strengthens your business reputation.

Read more: Warehouse Management System: Business Applications and Case Studies.

Challenges Addressed by a Custom Inventory Tracking System

1. Stockouts and Overstock Situations

Challenge: Unplanned stockouts or excessive inventory can cripple operations and strain relationships with clients.

Solution: Real-time visibility allows for proactive inventory management, preventing stockouts and overstock situations. The system sends alerts when stock levels approach predefined thresholds, empowering you to take preventive action.

2. Manual Errors in Tracking:

Challenge: Manual tracking methods are prone to human errors, leading to discrepancies in records and financial reporting.

Solution: Automation eradicates the potential for errors, ensuring accuracy in tracking and reporting. This not only saves time spent on rectifying mistakes but also builds trust with stakeholders.

3. Inefficient Order Fulfillment:

Challenge: Slow and inaccurate order fulfillment can result in dissatisfied customers and harm your brand reputation.

Solution: An inventory tracking system provides real-time insights into stock levels, enabling efficient order processing. This leads to faster order fulfillment, improved customer satisfaction, and a competitive edge.

4. Lack of Data-Driven Decision Making:

Challenge: Without real-time data, decision-makers are forced to rely on intuition rather than insights.

Solution: The system’s data analytics capabilities empower decision-makers with actionable insights. This data-driven approach facilitates strategic decision-making and allows for quicker adaptations to market changes.

The Case for Custom Inventory Tracking

In supply chain management, precision and efficiency are vital for success. Off-the-shelf solutions may appear attractive, but investing in a custom inventory tracking system is a strategic imperative. Here’s why:

1. Precision Aligned with Your Unique Needs: Off-the-shelf solutions lack specificity, designed for a broad audience. A custom system is tailored to your unique operations, ensuring seamless alignment with your processes, from order fulfillment to warehouse management.

2. Real-Time Adaptability: Custom solutions offer real-time adaptability to changing market conditions, technological advancements, and industry standards. This agility ensures you stay ahead without being confined by pre-set functionalities.

3. Cost-Effective Scalability: Off-the-shelf solutions often come with unnecessary features or limitations, hindering growth. Custom inventory tracking systems offer scalable, cost-effective solutions, allowing you to expand or modify functionalities without unnecessary overheads as your business evolves.

4. Seamless Integration: A custom solution ensures seamless integration with your existing suite of tools, from ERP to CRM systems. This creates a unified ecosystem, optimizing workflow, enhancing data accuracy, and improving overall operational efficiency.

Read more: Understanding The Types Of Warehouse Management Systems

5. Enhanced Security: Generic systems employ a one-size-fits-all security approach, leaving businesses vulnerable. A custom inventory tracking system enables personalized security measures, safeguarding sensitive data and mitigating risks specific to your industry and operations.

6. Maximized User Adoption: The effectiveness of a system hinges on its user adoption rate. Custom solutions prioritize user experience, aligning interfaces with your team’s familiarity. This minimizes training requirements, facilitating a smooth transition and maximizing the efficiency of your inventory management system.

7. Tailored Reporting for Decision-Making: Unlike pre-packaged systems, a custom inventory tracking system allows you to tailor reporting functionalities. It ensures the data you receive is not just comprehensive but directly aligns with your business goals, providing precise insights for strategic decision-making.

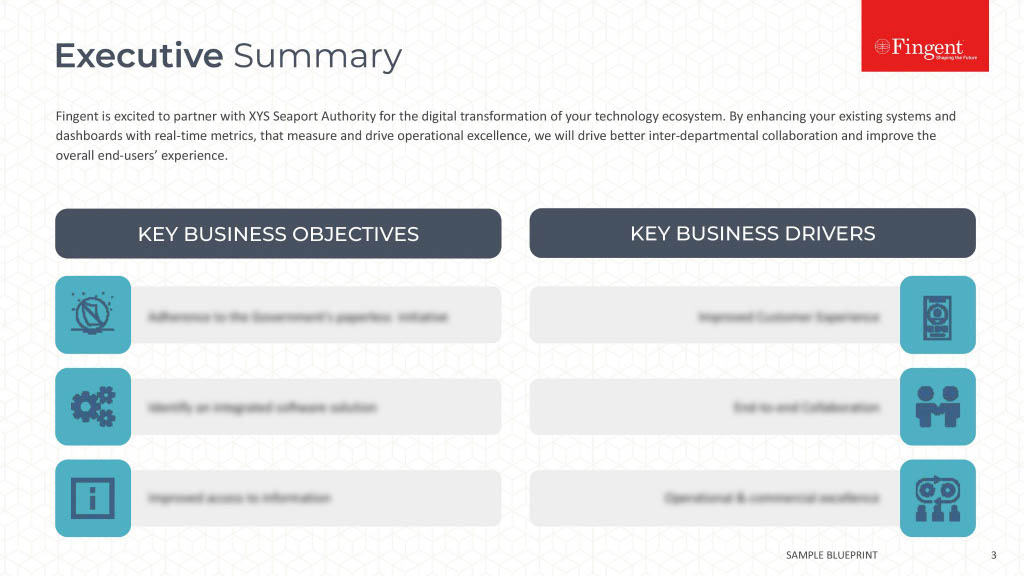

Elevate Your Supply Chain with Fingent’s Custom Inventory Tracking Solutions

At Fingent, we’re your dedicated partner for supply chain excellence, specializing in crafting tailored inventory tracking systems. Our solutions seamlessly adapt in real-time, ensuring agility in dynamic market landscapes. With a focus on scalability without unnecessary costs, we seamlessly integrate with your systems for enhanced efficiency. Leverage our expertise in custom reporting for actionable insights, backed by a proven track record in diverse industries. Partner with Fingent for precise, adaptable, and scalable supply chain solutions.

Get in touch with us, and let’s talk.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

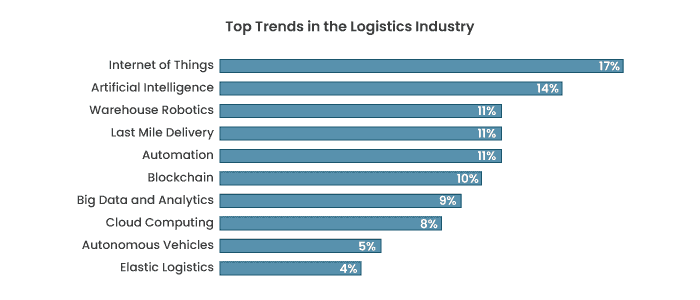

Artificial Intelligence (AI) evolved from a concept of science fiction to a transformative force that permeates our daily lives. From autonomous vehicles to voice assistants, AI has already made significant inroads in various sectors.

However, one area that stands to gain immensely from AI’s potential is the supply chain. As the backbone of global trade, the supply chain encompasses complex networks and intricate logistics. It is an ecosystem where efficiency, accuracy, and agility can make or break success.

With its vast array of applications, AI has the potential to streamline operations, enhance decision-making, and unlock untapped opportunities. In this journey through AI’s rising capabilities, we will delve into real-world use cases that demonstrate how AI is revolutionizing the supply chain. Furthermore, we will also explore the specific benefits that AI brings to the supply chain domain.

Role Of AI Optimizing the Supply Chain

Every business owner dreams of a supply chain that is finely tuned, seamlessly efficient, and adaptive to every twist and turn of the market. A business where warehouses run like clockwork, shipments arrive precisely on time, and customer demands are anticipated with uncanny accuracy is not a far-fetched dream; it’s a reality being shaped by the game-changing role of Artificial Intelligence (AI) in optimizing supply chain operations.

At the heart of AI’s transformative influence are three key components that work in harmony to revolutionize the supply chain landscape. Let’s uncover their captivating role in reshaping the future of supply chains.

- Machine Learning and Predictive Analytics: Machine learning and predictive analytics in the supply chain are like having a trusted, experienced mentor by your side, whispering valuable insights and guidance into your ear. Machine learning algorithms analyze vast amounts of historical data to uncover patterns, trends, and potential pitfalls.

- Natural Language Processing and Chatbots: Natural Language Processing (NLP) allows you to simply ask a question about your supply chain and receive instant, accurate answers. With a chatbot available 24/7, customers can get instant responses, while supply chain teams can focus on strategic decision-making.

- Robotics and Automation: Robots, equipped with advanced sensors and AI algorithms, can perform repetitive tasks with unmatched precision and speed. From inventory management to order fulfillment, these tireless machines streamline operations, reduce errors, and enhance efficiency.

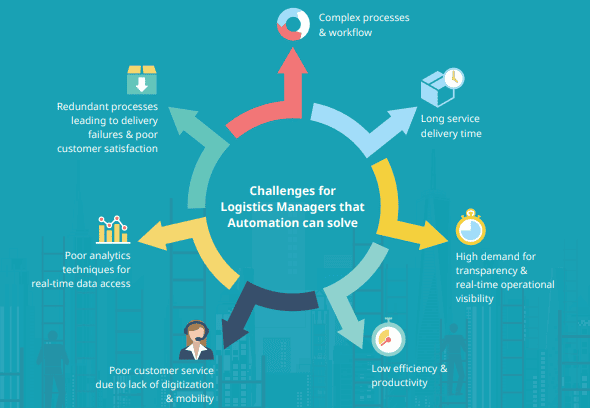

How AI Solves Supply Chain Challenges

The world of supply chain management is like a complex maze with numerous challenges at every turn. Thankfully, AI emerges as the trusty guide, equipped with the tools to solve some of the most daunting hurdles. Here are some for your reference:

1. Demand Forecasting and Inventory Optimization: This AI-powered assistant acts as your supply chain ‘savant,’ it understands your historical consumption patterns, market trends, and even factors like seasonality or promotional events.

2. Supplier Selection and Relationship Management: Choosing the right suppliers and maintaining strong relationships is like finding the perfect dance partner. AI steps in as a knowledgeable matchmaker. By analyzing vast amounts of supplier data, performance metrics, AI algorithms can assess and rank potential suppliers based on criteria such as reliability, quality, and cost.

3. Warehouse and Inventory Management: AI acts as a vigilant warehouse manager, optimizing layout, guiding picking and packing processes, and even predicting optimal storage locations. With AI-powered systems, warehouses can maximize space utilization, minimize errors, and accelerate order fulfillment, resulting in streamlined operations and satisfied customers.

4. Transportation and Logistics Optimization: AI takes on the role of coordinator who has a bird’s-eye view of the entire transportation network, utilizing algorithms to analyze real-time data on factors like traffic, weather conditions, and delivery constraints. By optimizing routes, load planning, and vehicle assignments, AI enables efficient transportation management.

5. Quality Control and Defect Detection: Think of a diligent quality inspector who never misses a flaw in a product. AI becomes this meticulous inspector, utilizing computer vision and machine learning algorithms to analyze visual data and detect defects with remarkable accuracy.

6. Risk Management and Supply Chain Resilience: AI plays this vital role just like a risk management expert. It analyzes a wide range of data sources to identify potential risks and vulnerabilities, ensuring supply chain resilience in the face of uncertainties.

7. Customer Service and Satisfaction Enhancement: AI takes on the role of a customer service representative who can swiftly address customer inquiries, provide accurate information, and resolve issues with ease. AI-powered customer service tools offer instant responses, personalized recommendations, and seamless assistance, enhancing customer satisfaction and loyalty.

Watch: Artificial Intelligence – how to navigate AI if you are not a tech company.

Remarkable Real-world examples of AI in the Supply Chain

AI transforms supply chain management like never before. Don’t take our word for it. See it in action as implemented by big players in the industry:

Use Case 1: Precision Prediction by Amazon

Problem: Traditional demand forecasting and inventory management methods often struggle to predict customer demands and optimize inventory levels in real-time accurately.

Solution: To address this challenge, Amazon has harnessed the power of AI algorithms to revolutionize demand forecasting and inventory management. By analyzing vast amounts of customer data, historical sales patterns, and even external factors like weather forecasts, AI algorithms can accurately predict demand with remarkable precision.

This AI-driven approach allows Amazon to optimize inventory levels, ensuring that popular products are readily available while minimizing excess inventory and reducing the risk of stockouts. By aligning supply with demand, Amazon is able to enhance customer satisfaction and maintain a competitive edge in the dynamic e-commerce landscape.

Use Case 2: Substitution Solution by Walmart

Problem: In online grocery shopping, customers often encounter situations where certain items they ordered are out of stock. This can lead to dissatisfaction and inconvenience, as customers may have to manually search for suitable substitutes or go without the desired product.

Solution: To address this issue, Walmart has implemented an AI-driven product substitution system. Using advanced algorithms, the system analyzes product attributes, customer preferences, and available inventory data to suggest suitable substitutions for out-of-stock items.

When an ordered item is unavailable, the AI system automatically identifies the best possible substitute based on factors such as brand, size, price, and customer feedback. It takes into account the customer’s past purchase history and preferences to make personalized recommendations. The system provides clear and transparent information to customers, ensuring they are aware of the substitution and have the option to accept or reject it.

Use Case 3: Real-Time Routing by UPS

Problem: Traditional route planning methods often struggle to optimize delivery routes efficiently, resulting in inefficient use of time, resources, and fuel.

Solution: UPS leverages AI algorithms for route optimization, enabling them to analyze real-time data on factors such as traffic patterns, delivery constraints, and even weather conditions. By considering these variables, UPS can generate optimal delivery routes that minimize distances, reduce fuel consumption, and optimize delivery time.

Through the implementation of AI in its logistics operations, UPS achieves significant cost savings, improves delivery efficiency, and reduces its carbon footprint. This AI-driven approach allows UPS to stay ahead of the competition and provide exceptional service to its customers.

Use Case 4: Valuable Vending by Coco-Cola

Problem: Traditional vending machines often lack the ability to gather real-time data on customer behavior and gauge the effectiveness of different brands and product offerings.

Solution: To overcome these limitations, Coca-Cola has implemented AI-enabled next-gen vending machines. These machines are equipped with advanced sensors, cameras, and AI algorithms that gather real-time data on customer behavior, purchasing patterns, and brand preferences.

With this newfound understanding, Coca-Cola can optimize product placements, tailor offerings to specific locations, and develop targeted marketing campaigns. Furthermore, the AI-enabled vending machines also allow Coca-Cola to remotely monitor inventory levels, predict demand patterns, and optimize restocking schedules. This ensures that the vending machines are always well-stocked with popular products, reducing the likelihood of stockouts and maximizing sales opportunities.

Use Case 5: Wonder Warehouses by Alibaba

Problem: Traditional warehouse management practices often face challenges related to inefficient storage utilization, suboptimal picking processes, and delays in order fulfillment.

Solution: Alibaba has embraced AI technology to develop smart warehouses that leverage automation, robotics, and AI algorithms. These AI-enabled warehouses optimize storage utilization, streamline picking and packing processes, and enable efficient order fulfillment.

Through the integration of AI, Alibaba achieves faster and more accurate inventory management, enhances warehouse operations, and improves overall efficiency in its supply chain. This innovative use of AI allows Alibaba to meet the demands of the e-commerce market and deliver exceptional service to its customers.

Checkout out our Infographic: Successful Logistics and Warehouse Management Practices.

Solid Supply Chain Solution with AI by Fingent

Advancements in AI technologies continue to shape the supply chain landscape, with machine learning algorithms becoming more sophisticated, natural language processing capabilities evolving, and robotics and automation becoming increasingly intelligent and adaptable. These advancements enable businesses to make data-driven decisions, automate repetitive tasks, and optimize operations like never before.

At Fingent, we understand the immense potential of AI in supply chain management and are committed to helping businesses harness its power. Our expertise lies in developing innovative AI solutions tailored to specific industry needs, integrating AI with emerging technologies, and driving digital transformation in the supply chain.

Whether it’s building intelligent forecasting models, implementing AI-powered automation, or leveraging AI-driven analytics, Fingent is dedicated to empowering organizations to thrive in the AI-driven supply chain landscape.

Businesses that embrace its potential will gain a significant competitive advantage. By leveraging AI technologies, integrating with emerging technologies, and partnering with experienced custom software solution providers like Fingent, organizations can unlock new frontiers of efficiency, innovation, and success in the dynamic world of supply chain management.

Reach out to us to get the best supply solution for your business.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

The onset of globalization has encouraged business operations on an international scale. It offers companies the opportunity to reach new customers in new markets. Exposure to unknown markets and sometimes even known markets can expose businesses to greater competition and greater risk. However, efficient management of the supply chain can do away with many of these risks and put you on the path to success.

The challenges in the supply chain can include being unsure of the reliability of your suppliers, and their quality, cost, lead time, lot size, and more. Your business will surely profit if you had a way to monitor your supplies and the risks to your business.

Yes, clear visibility is crucial.

This is where custom software can benefit your business!

Custom software equips you with a way to collect, organize, and monitor the supplier-related information that is most meaningful to your business. This blog discusses which functions of the supply chain can be better managed with custom software and also talks about the benefits this can bring to your business.

Why Is Customized Supply Chain Management Software Important?

Efficient management of the supply chain depends primarily on data gathered at each stage of the supply chain process. The success of the business hinges on the way companies use those insights to make decisions that optimize demand, supply, inventory, and deliveries.

That is why custom software is essential to managing the supply chain. Custom software can enable organizations to make better use of their data as it gives structure to the information already in their possession.

Through the use of custom software solutions, companies can identify faults in their supply chain process. Such visibility can help them make better inventory decisions or inform their customers of the shipping status for their confirmed orders.

Essentially, custom software is instrumental in improving business operations and relationships with both customers and suppliers.

Read more: Build or Buy Logistic Software: An End To The Prolonged Discussion

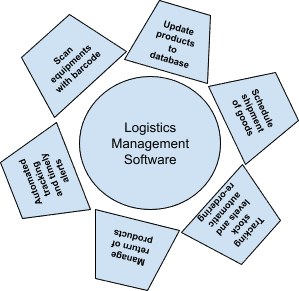

Manage Key Supply Chain Functions with Custom Software

Every business is unique in its functions. A software can address the specific company challenges only when customized and tailor-built after crucially analyzing the workflows and industry pain points. Here are a few to look into.

- Raw material acquisition: Supply chain management is a journey, and purchasing is at the beginning of that journey. Purchasing includes sourcing raw materials and other resources. Custom software enables smooth coordination with suppliers to deliver the material without any delays requires.

- Planning and forecasting: The operations team must anticipate the possible market demand and the number of units for production. Over-anticipated demand can result in excess inventory costs. If it is underestimated, then the company will not be able to meet its customer demand and thus lose revenue. Custom solutions for planning and forecasting can help the operations team to anticipate demands more accurately.

- Warehouse arrangement: Supply chain management requires warehouse arrangements till it is shipped for delivery. If the products are delivered outside the country or state limits, there will also be a need for outstation warehouses. Custom software can optimize logistics to reach end-point delivery without any glitches.

Advantages Of Custom Software in Supply Chain Management

1. Increased transparency throughout the supply chain

Knowing exactly where your item is at any given time is important for all businesses as it allows you to sell the item before it even reaches your warehouse. Custom software can help you sell this way because it can pinpoint the exact location of your item and the time that it will reach your warehouse.

This will allow you to provide a guarantee to your customer that he will receive the product he purchased. Streamlining the supply chain will help achieve faster response times and increase customer loyalty.

2. Efficient inventory management

With the help of custom software, you can sell your item while it is on the move or as it is in the making. It can help you estimate how many items you must produce, eliminating excessive production.

3. Supplier management

You can keep a good relationship with your suppliers with custom software. Real-time data will allow you to know if you are running out of stock or if your tools and equipment need repair or replacement. This data will help you contact your suppliers immediately and thus minimize any potential delays.

You will also have details such as account receivables and other information at your fingertips when dealing with your suppliers. This will ensure that you are up to date with payments and discounts. As a result, you notice that your communication and cooperation with dealers and vendors improve considerably.

4. Streamline Processes

Custom software will create highly streamlined processes for supply chain management, especially for businesses that operate from different locations across the globe.

Fully customized software enables companies to accumulate all business data in one centralized location. Employees greatly benefit from this as they can now gain access to the latest versions of data, even if they are accessing it from multiple locations or branches.

5. Un-bottleneck your supply chain

Bottlenecks in the supply chain are a direct result of the ineffective system in place that does not allow teams in different locations to communicate and align statuses to fulfill overall objectives. Companies that experience such bottlenecks miss opportunities and lose customers because they are unable to provide what their customers want.

An unsatisfied customer walks out on you and straight into the open arms of your competition. If you are beginning to notice lower satisfaction rates, numerous complaints, or bad reviews from the customers, it is time to explore custom software that can give you a business-targeted approach to customer experience.

When a business looks to meet or exceed customer demands, they have to rely heavily on its supply chain. Internal bottlenecks can slow down the entire process and risk order fulfillment. To prevent such bottlenecks, a business must understand what causes them and how to prevent them.

Custom software can help a business identify such bottlenecks and thus help efficiently manage the supply chain.

Save Money, Time, and Your Business!

It is clear that custom software comes with many benefits. It is also obvious that it saves money with time. While off-the-shelf software may come with a lower initial cost, investing in custom software will give more benefits to the supply chain management cycle. It improves sales functions and boosts productivity.

Custom software that is fully optimized to the supply chain will improve business function in a way no off-the-shelf software can. Fully optimizing the supply chain process can be lean and seamless through the use of custom software. If the business growth process is left unchecked by the off-the-shelf software solutions it can become highly chaotic. Custom software gives companies a higher level of control over all supply chain operations while taking control over the growth process.

A company that is digitally driven by custom software automatically enables a more proactive and open business. If this is what you want for your business, give us a call.

Our experts at Fingent thrive on creating custom solutions for our clients. They will be happy to talk through the game plan with you and show you how your business can excel with custom software for your supply chain.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new