Tag: Warehouse management

Streamline And Enhance Your Warehouse Management Operations With SAP EWM

Worldwide, companies spend an average of €300 billion a year on warehousing, either in-house or through third-party logistics. The rise of eCommerce and the growth of global supply chains increase warehousing operations costs for enterprises. In addition, with the pandemic heightening consumers’ interest in eCommerce, they expect instant delivery of products. To cater to this dynamic demand, some logistic companies increased the number of their seasonal employees. With this demand continuing to rise, it becomes imperative that warehouse management processes be optimized.

Read more: Warehousing Management System: Simplify Operations & Scale Your Business

Warehouse management is currently undergoing a modern-day makeover to meet growing demands. Therefore, industry leaders must take steps to optimize warehouse management to keep pace with faster requirements and ever-increasing volumes. SAP Extended Warehouse Management (SAP EWM) streamlines, simplifies and optimizes your warehouse operations. This blog considers how SAP EWM can benefit your business.

Challenges In Supply Chain Management Today

Supply chains are at the core of business operations. Therefore, supply chain management needs to overcome several challenges that impact the bottom line of their business.

Read more: Top Challenges Faced By Logistics Management Today

Here are some challenges companies should be aware of:

1. Identifying Bottlenecks In Customer Service

Customers’ demands have become extremely specific. Plus, they expect to be notified about any possible delays. Therefore, supply chain management can benefit from advanced planning and scheduling systems that can help them identify bottlenecks. This can help them prevent delays or notify the customer of a possible delay.

2. Gaining High Supply Chain Visibility

Overall production cost is affected by several factors that go unnoticed. High supply chain visibility will help the management increase the system’s efficiency and eliminate wasteful steps. Such visibility can contribute to cost control.

3. Finding The Right Talent

Hiring and retaining the right talent has become increasingly difficult. Hence, it is beneficial to have a performance tracking system that allows you to gauge employee productivity and spot the right talent that could be trained effectively.

Read more: Warehouse Automation: Streamlining Operations

4. Ensuring On-time Delivery

Delivering goods on time is another challenge that can make you lose your customers to your competition. You can resolve these challenges with planning and scheduling software. It can help you receive and deliver the material on time.

5. Maintaining An Agile Production Plan

Lack of an agile production plan that does not reflect market changes can lead to inefficiency of production. You can remain agile by having a planning and scheduling system. This system helps you keep a tab on the effect of market changes without disrupting your current schedule. Those insights equip you to make the best decisions in response to those changes.

Read more: Understanding The Types Of Warehouse Management Systems

How SAP EWM Can Benefit Your Business

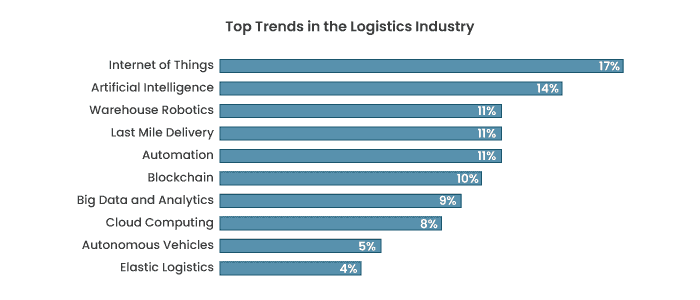

Statista forecasts the global warehouse automation market to surpass 30 billion U.S. dollars. And, Zebra warehousing vision study shows that 80% of organizations plan to invest in new technologies to be competitive. And 27% plan to utilize full automation by 2024. SAP EWM helps you capitalize on this.

Read more: How Robotics In Logistics Helps Improve Supply Chain Efficiency

SAP Extended Warehouse Management (EWM) is fast, agile, and powerful. It is designed to future-proof current supply chain technology and help your business grow.

SAP EWM can be deployed into many business environments. It can support both simple and complex warehouse processes at the granular level. It is a high-speed system that makes supply chain management more accessible and more efficient. SAP EWM can be configured to the organization’s specific needs and can be streamlined over different locations.

Here are some other ways your business can benefit from SAP EWM:

1. Optimize Task Management

In a standard warehouse, one person can be seen going to the same stock bin several times during the day. This happens when all orders that need to be picked for a day appear together, making it difficult to break them down.

You can optimize the picking process with SAP EWM. The platform uses various algorithms to employ the most efficient way to complete as many tasks as possible. This prevents pickers from wasting their time as they have to tread the same path constantly. Plus, SAP EWM’s voice picking functionality enables shorter search time and minimizes errors.

Read more: How SAP Helps Realize Voice-enabled Warehouse Operations

SAP EWM can easily integrate all processes to provide easy end-to-end operations management. It can take the burden off your team for outgoing shipments allowing them to tackle inevitable snags that need to be addressed.

You can link SAP EWM with your transportation management system for greater accuracy for delivery targets. It provides your company a holistic outlook alerting your team when to expect delays and other time-sensitive information.

2. Streamline Labor Management

Efficient use of time, effort, and resources can contribute to business growth. This is another point where SAP EWM can integrate with your WMS. The platform can provide structure in the workplace. With a good framework, each worker knows their location and responsibilities. Such an organized structure will help your employees enjoy more efficient task allocation.

SAP EWM generates real-time insights on workers’ performance, enabling managers to offer more constructive suggestions to improve efficiency. Subsequently, your employees develop more efficient and consistent work habits.

3. Control Costs

Not following the first-in, first-out method for perishables and inefficient use of space and labor can increase wastage. SAP EWM can help reduce wastage of perishables by identifying which units need to be picked first.

SAP EWM can maximize the use of the warehouse space by optimizing the location for each pickup time. It optimizes your space and the travel path of the pickers. All this will reduce your on-hand inventory and reduce your space costs without compromising on quality.

4. Boost Customer Relationship

SAP EWM can reduce delivery lead times and order accuracy errors. This increases customer satisfaction and results in more sales. Thus, SAP EWM elevates and improves relationships with your suppliers and end customers.

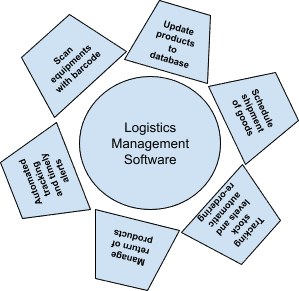

Read more: Logistics Management Software – Everything You Should Know

Leverage SAP EWM Capabilities With Fingent

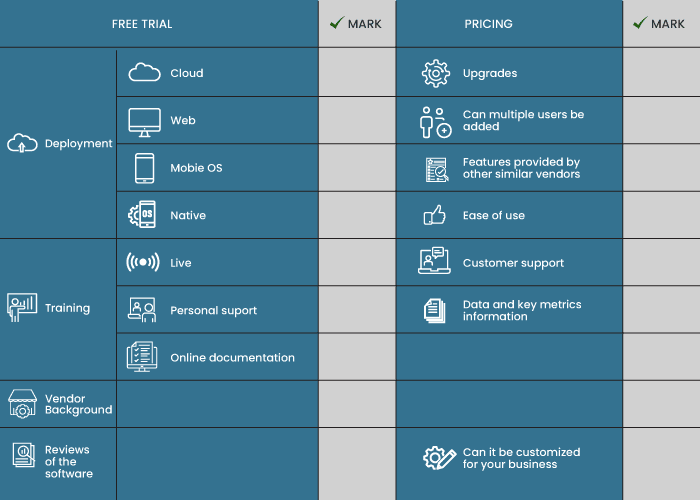

Logistics providers must evaluate the best warehousing management solution for their specific needs. If your business is at a crossroads in choosing the best option for your warehouse operations, Fingent is here to help. Feel free to contact us to learn more about how SAP EWM can transform your business.

Fingent is a certified SAP silver partner and has assisted global businesses in successfully implementing SAP EWM. Our custom software development experts can guide and help you explore the flexibility in deploying SAP EWM and ensure it is the best fit for your specific business requirements.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new

Talk To Our Experts

SAP helps increase warehouse management productivity with voice picking!

Voice technology has been there for a while and is here to stay. Its increasing adoption among warehouse distribution centers has led to increased accuracy, improved productivity, and training time reduction. Supply chain executives report attaining a 50% decrease in picking errors and a typical ROI in less than one year with voice integration.

In retail warehouses, complex facilities such as inventory control are vital, with several picks to be performed every hour. The warehouse employees should be an efficient and accurate while ‘picking’ as wrong picking can lead to incorrect deliveries and affect customer satisfaction.

To improve staff accuracy and speed of pick, warehouses can consider “Voice Picking” technology. Voice picking is an extension of the Warehouse Management System (enhanced by additional software and hardware) that allows transferring instructions to the warehouse operators using earphones and microphones. Voice Picking uses a wearable computer that includes a headset and microphone so that the order pickers can be instructed on what items to pick from where and later confirm their actions verbally into the Warehouse Management System (WMS).

Read more: How Robotics in Logistics Helps Improve Supply Chain Efficiency

Benefits of Voice-picking

A voice-picking system creates a hands-free, heads-up workflow. Unlike the traditional warehouse order picking, where you need to stop to read, scan, or punch keys, the voice-picking system allows users to listen and speak efficiently. Some of its benefits include:

- Productivity improvement

- Reduction in errors by 25% or more

- Decrease in accidents as operators rely on eyes and hands-free technology and hence are more aware of the surroundings

- Cuts training time

How is voice-enabled warehouse operation helping during the COVID-19 pandemic?

In the last few months, warehousing and logistics have been hit hard. While there was enormous pressure on the warehouse to execute deliveries quickly due to increasing customer expectations, COVID-19 has caused further disruption.

Logistic companies have had to evaluate options and make changes across transportation modes, considering delays, interruptions, and price changes.

According to a survey from August to September 2020, about 32,200 jobs were added to the warehouse and storage sector. Thanks to voice and device technology! Voice integration helped address the labor shortage and equipped new workers. Here are a few benefits of voice-enabled warehouse management.

1. Efficient onboarding

New workers can pick up their barcode scanner or mobile device and begin their work with minimal onboarding time. Latest device upgrades offer improved designs and user-friendly interfaces. Whether a Windows 10, iOS, or Android device, workers can choose the device they like. This flexibility helps simplify the training and onboarding process of new workers, optimizing workforce management, and making it a more efficient experience.

New workers can get started quickly without the need for lengthy training processes. With voice-enabled applications, you can reduce the training time from several hours to just a few minutes.

2. Increased productivity

Voice capabilities are helping workers to keep pace with the high volume of orders. It helps them cope with the increased pressure to meet soaring demands, reduce training time, and use the hand-held devices of their comfort.

3. Higher accuracy

With hands-free wearables and voice picking, workers don’t need to stop frequently to check their devices. It will reduce errors and allow pickers to complete more orders within the same timeframe with improved speed and accuracy.

4. Improved safety

The coronavirus has made “contactless” mandatory. Voice picking can eliminate many physical touchpoints that can lead to virus exposure. Minimizing surface contact is one of the best ways to protect warehouse workers.

Read more: Contactless services: The new retail norm

How does SAP help voice-picking?

SAP’s open architecture supports several voice integration methods that help users achieve immense productivity and accuracy. If your business is running on SAP’s Extended Warehouse Management (EWM) solution or Warehouse Management (WM), voice can be easily integrated. It results in the seamless integration of ERP with your warehouse management solutions and voice. Ultimately, the accuracy, productivity, comfort, and safety of all your warehouse processes will improve. It helps distribution centers deliver on time, achieve deadlines, and scale.

Read more: SAP Preconfigured Solutions Boost Efficiency Among Industries

Today, voice integrated into SAP has become an essential tool for many businesses. SAP’s voice picking provides superior ergonomics, eliminates distractions, and allows users to focus on the task. The voice technology is specifically designed to provide voice recognition in noisy environments. The noise cancellation ability helps lower warehouse background noise, such as truck horns, pallet drops, and conveyor system mechanism.

Additionally, the technology helps overcome language barriers as most systems come in more than 40 languages allowing users to interact with SAP most naturally and effectively.

Voice with SAP can quickly scale with your business both when your business grows and when you need to accomplish seasonal peaks. With SAP’s explicit instructions, you can add new employees’ onboarding time and capacity without any complex changes to the given infrastructure.

Download Our Case Study: How Fingent automated integration between SAP SuccessFactors and SAP S/4HANA

To conclude

As the economy battles to overcome uncertainty, using safe, cost-effective solutions, embracing advanced technologies like voice-enabled applications are imperative to sustain. Additionally, with COVID-19 showing no signs of ending soon and the world shifting to contactless shopping, embracing voice-enabled applications makes sense from an economic and physical safety standpoint.

No other technology has impacted the logistics and shipping industry like voice in the recent past. Extend your logistics and fulfillment processes by making voice technology a vital ingredient of your company’s IT strategy. Contact us now to get started.

Stay up to date on what's new

Featured Blogs

Stay up to date on

what's new